In the realm of plumbing systems, the significance of a non return valve cannot be overstated. According to the Plumbing Manufacturers International, nearly 30% of plumbing failures are attributable to improper drainage and backflow issues, emphasizing the need for reliable components within the system. A non return valve serves as a crucial safeguard against backflow, ensuring that waste and contaminated water do not re-enter clean water supply lines. By preventing reverse flow, these valves not only maintain the integrity of plumbing systems but also enhance overall efficiency, thus reducing the risk of costly repairs and health hazards. As such, incorporating the best non return valve into your plumbing infrastructure is not merely a recommendation; it is an essential practice that aligns with industry standards and promotes longevity and safety in water management.

Non-return valves are a vital component of plumbing systems, ensuring that water flows in one direction and preventing backflow. Their importance cannot be overstated as they play a critical role in maintaining water quality and safety within the plumbing infrastructure. Recent analyses highlight that specialized valves, such as Reduced Pressure Zone (RPZ) valves, are essential not only in commercial settings but also for residential plumbing systems, particularly in minimizing contamination risks associated with backflow—a significant concern for public health.

Non-return valves are a vital component of plumbing systems, ensuring that water flows in one direction and preventing backflow. Their importance cannot be overstated as they play a critical role in maintaining water quality and safety within the plumbing infrastructure. Recent analyses highlight that specialized valves, such as Reduced Pressure Zone (RPZ) valves, are essential not only in commercial settings but also for residential plumbing systems, particularly in minimizing contamination risks associated with backflow—a significant concern for public health.

Understanding the implications of backflow regulations is crucial for plumbers and system designers. With the potential hazards posed by pathogens like Legionella, particularly in hot water systems, implementing proper backflow prevention methods can significantly reduce contamination risks. Reports indicate that incidents related to water safety in food manufacturing facilities necessitate stringent plumbing standards. Therefore, choosing the right non-return valve is central to upholding these standards and ensuring a safe water supply.

Tips for optimizing plumbing systems include regularly inspecting non-return valves to confirm they are functioning properly. Additionally, consider investing in specialized valves for areas prone to backflow. It’s beneficial to consult with plumbing professionals to assess and reinforce compliance with local regulations to ensure water safety in your facility or home.

Non-return valves, often overlooked in plumbing systems, play a crucial role in preventing backflow, a phenomenon that can lead to serious issues within your home. Backflow occurs when water reverses its intended direction, which can compromise the safety and quality of your water supply. By installing a reliable non-return valve, you create a one-way path for water, ensuring that it flows in a controlled manner and preventing contaminants from entering your clean water lines. This is particularly vital in areas where potable water sources are adjacent to wastewater lines.

In addition to safeguarding your water quality, non-return valves protect your plumbing infrastructure from damage. In the event of pressure fluctuations or surges, water can be forced back into pipes, resulting in leaks, burst pipes, or even flooding. A high-quality non-return valve acts as a barrier, absorbing these pressure changes and maintaining stability within the plumbing system. This simple device not only enhances the longevity of your plumbing but also contributes to a healthier living environment by mitigating the risks associated with backflow.

Prioritizing the installation of non-return valves can lead to lasting peace of mind for homeowners, protecting both your property and your family's well-being.

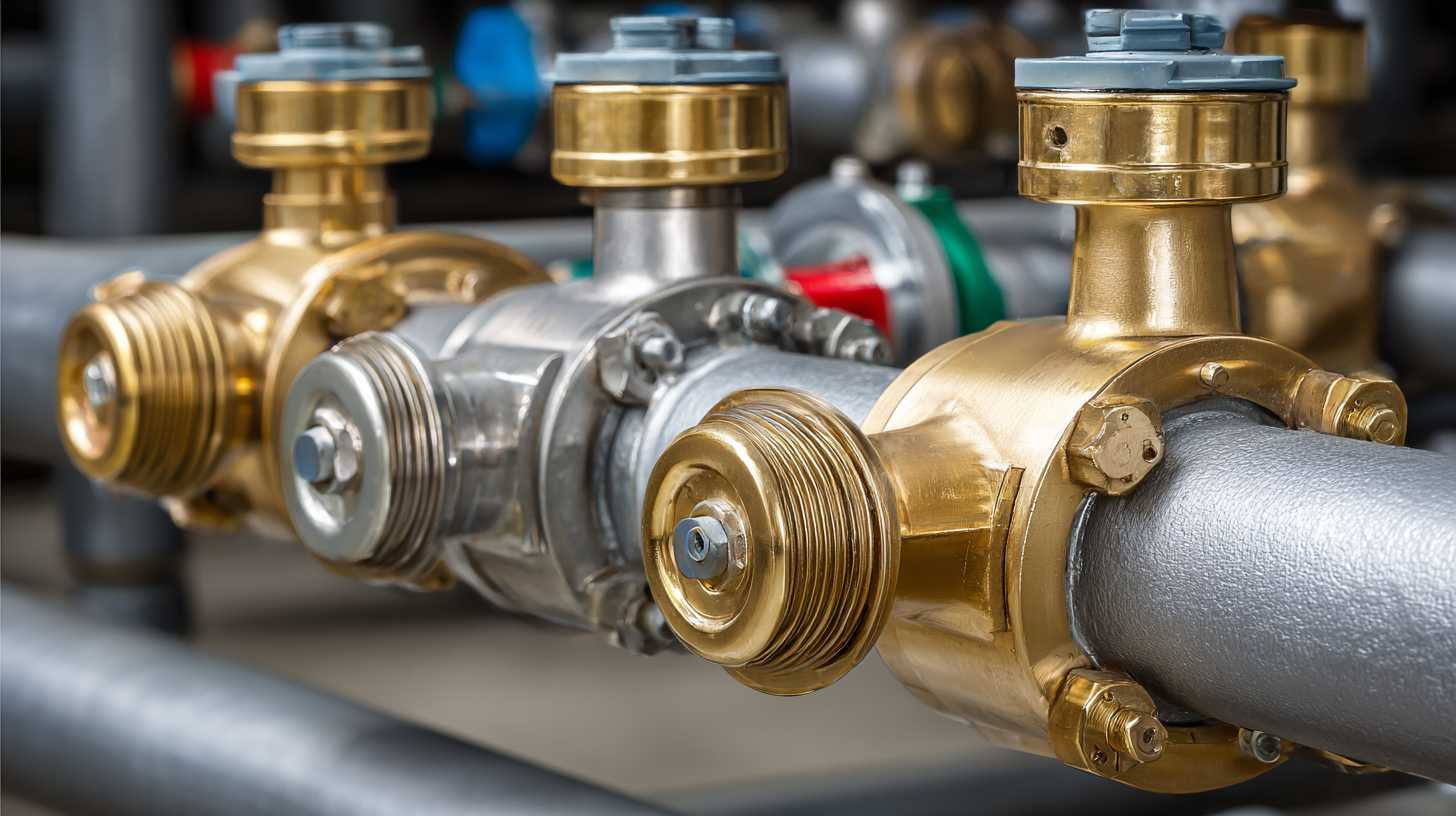

When selecting the best non-return valve for your plumbing system, there are several key features to consider that can significantly impact performance and longevity. First, look for valves made of high-quality materials, such as brass or stainless steel, which offer durability and resistance to corrosion. A robust construction ensures that the valve will withstand varying pressure levels and environmental conditions, reducing the risk of leaks or failures.

Another essential feature is the valve's design, particularly its flow mechanism. A well-designed non-return valve will operate smoothly, allowing for easy opening and closing while preventing backflow. Consider options with a silent or slow-close mechanism to minimize noise and water hammer effects in your plumbing system. Additionally, check the valve's size and compatibility with your existing pipes. Proper sizing ensures effective operation and avoids issues related to pressure buildup or inadequate flow. By focusing on these key features, you can ensure that your plumbing system remains efficient and reliable.

When considering the best non-return valves for your plumbing system, it's essential to understand the leading brands and their unique benefits. Brands like Oatey, NIBCO, and Watts have established themselves as top contenders in the market. Oatey's non-return valves are renowned for their durability and ease of installation, making them a top choice for both DIY homeowners and professional plumbers. NIBCO offers a range of valves that not only prevent backflow but also provide corrosion resistance, ensuring longevity in various environments.

Tips for selecting the right non-return valve include considering the specific requirements of your plumbing system. Assess the pressure rating and material compatibility to avoid failures. Additionally, always review the warranty and customer support options provided by the manufacturer; a reliable brand will ensure peace of mind as you install their products. Watts, for instance, provides excellent customer service and an extensive warranty, further solidifying its reputation as a dependable choice in the plumbing industry.

Always remember to install non-return valves in the right orientation and check regularly for any signs of wear or leaks. Proper maintenance and timely replacements will ensure your plumbing system stays efficient and free from the hindrances of backflow. Understanding the distinct benefits of each brand can greatly improve your plumbing experience, keeping your system functioning smoothly.

| Reason | Benefit | Performance | Material | Maintenance |

|---|---|---|---|---|

| Prevents Backflow | Ensures clean water supply | Highly efficient | Brass or PVC | Low maintenance needs |

| Enhances System Longevity | Reduces wear and tear | Stable performance over time | Stainless Steel | Minimal upkeep |

| Improves Safety | Prevents contamination | Reliable under pressure | Nylon or Polypropylene | Easy to check |

| Energy Efficiency | Saves water and energy | Optimizes flow rate | Copper | Long lifespan |

| Cost-Effective | Reduces repair costs | High durability | PVC | Low intervention required |

| Versatile Use | Applicable in various systems | Flexible installation options | Various materials available | User-friendly design |

| Flow Control | Maintains consistent water flow | High precision | Alloy Composites | Simple adjustments |

Maintaining the longevity of your non-return valve is crucial for a well-functioning plumbing system. These valves are designed to prevent backflow, ensuring that wastewater or other fluids do not return to your clean water supply. To keep them running smoothly, regular inspection is key. Look for signs of wear and corrosion, and ensure that the valve opens and closes properly without any obstruction. Addressing minor issues early can prevent larger problems down the line, extending the life of your valve and safeguarding your plumbing.

Another important maintenance tip is to ensure that the valve is kept clean. Accumulation of debris can impede the function of the non-return valve, making it less efficient. Periodically flush the valve with clean water to remove any buildup, and consider using a gentle cleaning solution if necessary. Additionally, check the sealing mechanisms for any signs of degradation, as a damaged seal can lead to leaks and compromise the effectiveness of the valve. By incorporating these maintenance practices, you can significantly enhance the performance and durability of your non-return valve, thus protecting your entire plumbing system.