Event

IMI to unveil new product line at ADIPEC 2024 in Abu Dhabi

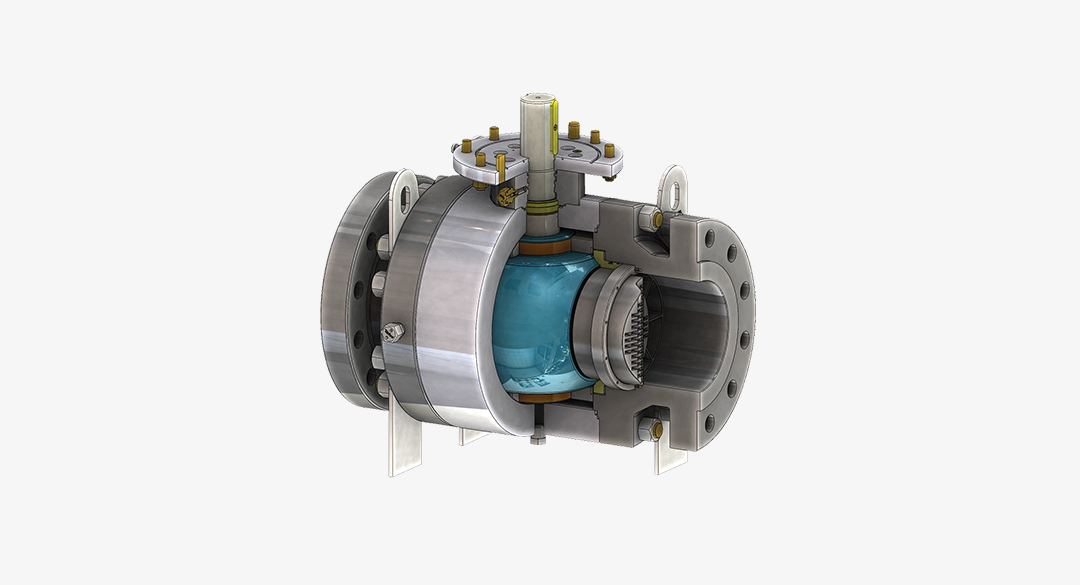

Join us at ADIPEC 2024 to discover IMI’s expertise in advanced flow control and valve solutions for the oil and gas industry. With a comprehensive range of products supporting safe and efficient operations, we’re showcasing our specialised instrumentation solutions at the event, including valve automation, solenoid valves, and diagnostics technology.