Choosing the right stainless steel ball valve is crucial for ensuring the efficiency and durability of various industrial applications. According to a recent market analysis by Research and Markets, the global ball valve market is projected to reach USD 13.03 billion by 2025, growing at a CAGR of 5.1%. This significant growth highlights the increasing importance of selecting the appropriate valve type for specific operational needs. Stainless steel ball valves, known for their robust construction and excellent resistance to corrosion, play a vital role in sectors such as oil and gas, water treatment, and chemical processing. Understanding the key factors such as pressure ratings, temperature tolerances, and end connections is essential for making informed decisions that can enhance system performance and longevity. By navigating the complexities of stainless steel ball valve specifications, professionals can optimize their applications and ensure compliance with industry standards.

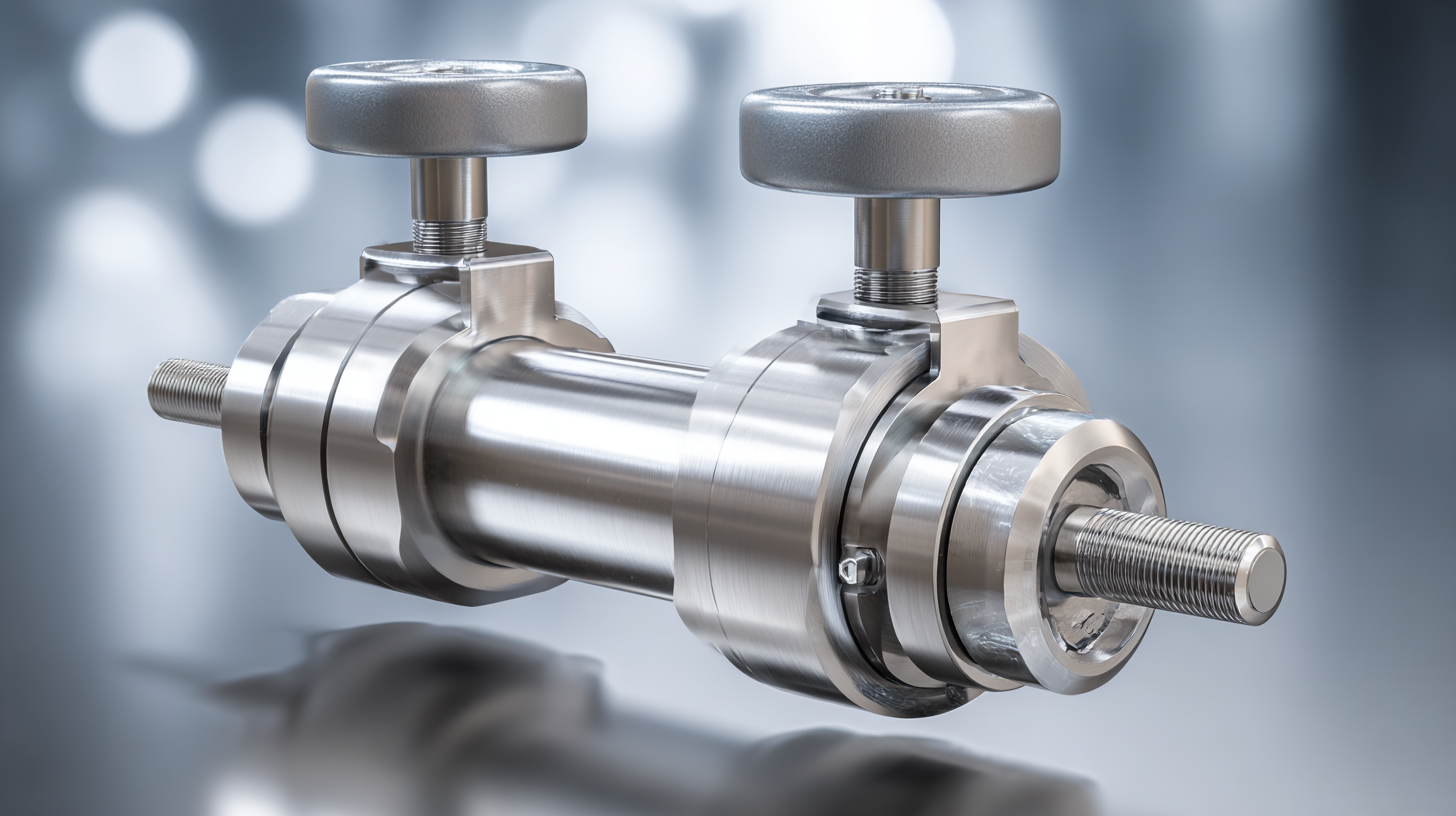

When selecting the right stainless steel ball valve for your applications, it's essential to understand the various types available and their specific uses. The most common types include floating ball valves, which are suitable for low-pressure applications, and trunnion-mounted ball valves, designed for high-pressure environments. According to a 2023 industry report by MarketsandMarkets, the demand for stainless steel ball valves is projected to grow substantially, driven by industries such as oil and gas, water treatment, and chemical processing.

Another critical aspect of choosing the right valve is the material's compliance with industry standards. For instance, stainless steel 304 and 316 are frequently used due to their superior corrosion resistance, with 316 being preferred for harsher environments, particularly in chemical applications. A study from the Valve Manufacturers Association indicates that improper valve selection can lead to increased maintenance costs by up to 30%.

Tips: When selecting a valve, consider factors such as pressure rating, temperature range, and compatibility with the fluid being controlled. Conducting a thorough analysis of your system's requirements can significantly improve efficiency and reduce operational risks. Additionally, consulting manufacturer specifications and industry reports can provide valuable insights into the best choices for your specific needs.

When selecting a stainless steel ball valve for a specific application, several key factors must be carefully considered to ensure optimal performance and longevity. Firstly, the material composition of the valve is critical. AISI 316 stainless steel is often recommended for its superior corrosion resistance, especially in chemical processing and marine environments. According to a report by the International Stainless Steel Forum, 316 stainless steel is known to provide adequate protection against pitting and crevice corrosion, making it suitable for harsh environments.

Another important factor is the valve's pressure and temperature rating. It is essential to match these ratings with the operational conditions of the system. The American National Standards Institute (ANSI) indicates that stainless steel ball valves can typically handle pressures ranging from 150 to 600 psi, depending on the specific design and size. Additionally, knowing the maximum operating temperature is crucial because exceeding these limits can lead to failure. For instance, valves rated for temperatures up to 200°C are common in steam applications, as highlighted in the latest report by the Valve Manufacturers Association. Therefore, a thorough understanding of the application requirements is vital to ensure the right choice of stainless steel ball valve.

| Factor | Description | Consideration |

|---|---|---|

| Material Grade | The type of stainless steel used (e.g., 304, 316) which affects corrosion resistance. | Consider chemical exposure and environmental factors. |

| Size | Nominal pipe size of the valve which influences flow rate and pressure. | Match the valve size with the existing piping system. |

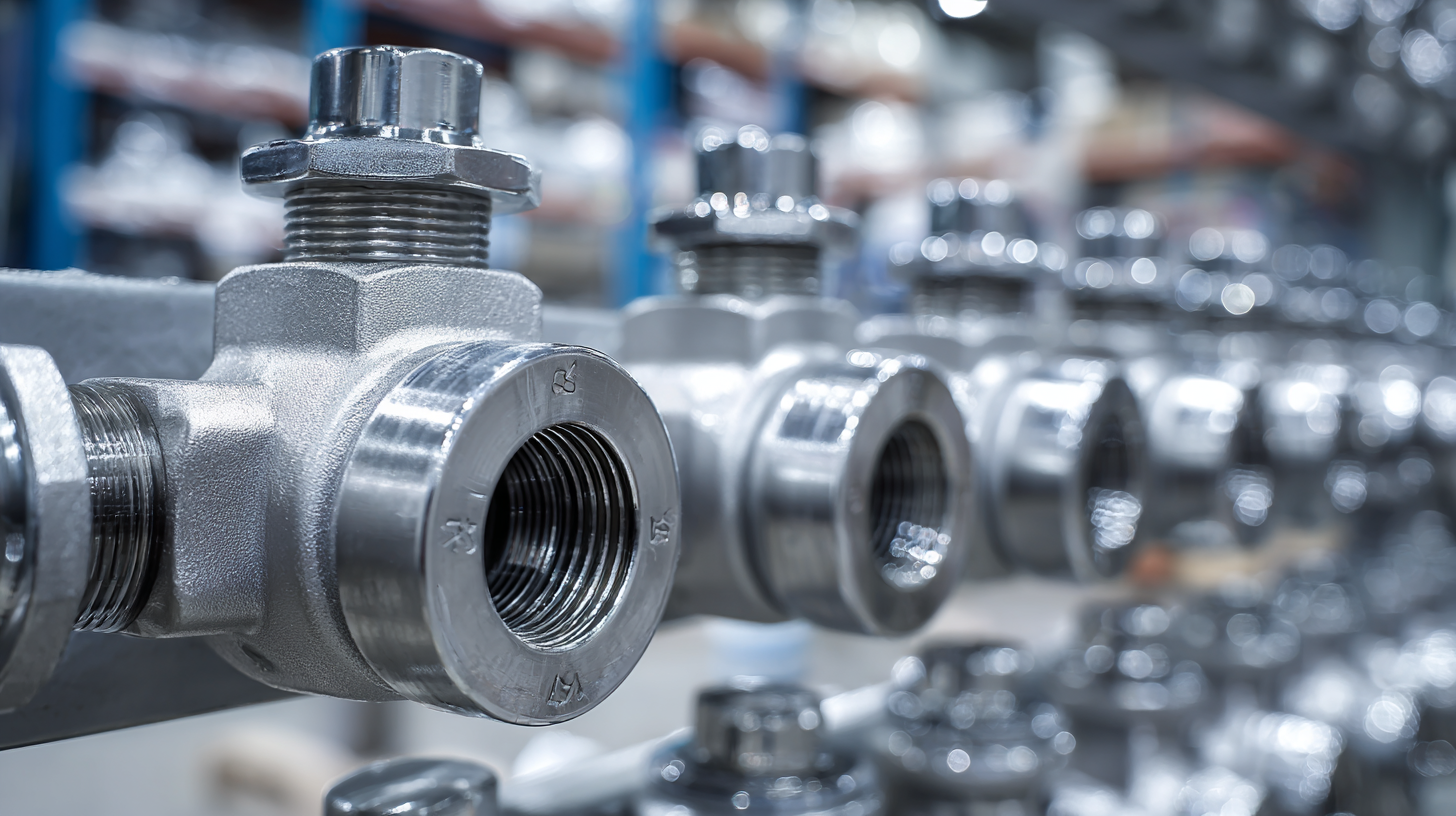

| End Connection Type | How the valve connects to the piping (e.g., threaded, flanged, welded). | Ensure compatibility with your system's connections. |

| Pressure Rating | The maximum pressure the valve can handle safely. | Select a valve with a higher rating than system requirements. |

| Temperature Range | The range of temperatures that the valve can operate within. | Ensure the valve material suits the process temperature. |

| Actuation Method | How the valve is operated (manual, pneumatic, electric). | Choose based on usage frequency and operational automation needs. |

| Flow Characteristics | The type of flow the valve is designed to handle (straight-through, throttling). | Consider whether precise flow control is necessary. |

| Certifications | Industry certifications and standards (e.g., ISO, ANSI). | Ensure compliance with relevant industry regulations. |

When choosing the right stainless steel ball valve for specific applications, it is crucial to assess the pressure and temperature ratings to ensure optimal performance. The pressure rating indicates the maximum pressure the valve can withstand, while the temperature rating reflects the highest temperature within which the valve can operate effectively. These parameters must align with the system’s operational conditions to prevent failures, leaks, or costly downtime.

In contexts such as the integration of advanced technologies in biodiesel production or the evaluation of thermal energy storage solutions, the operational stresses can be significant. For instance, in processes involving high temperatures and pressures, such as those found in Polymer-Electrolyte-Membrane (PEM) electrolysis systems, selecting a ball valve that maintains integrity under these conditions is essential. Additionally, research on innovative materials and design approaches can optimize performance and longevity, particularly in applications requiring high durability and efficiency. The right choice of valve directly impacts system reliability and overall efficiency, highlighting the importance of a careful evaluation of pressure and temperature capabilities in valve selection.

This chart illustrates the optimal pressure and temperature ratings for various stainless steel ball valve types based on their applications. The data indicates the range of pressures (in PSI) and temperatures (in °F) suitable for common industrial uses.

When selecting a stainless steel ball valve for specific applications, evaluating the compatibility with the fluids and media in your system is crucial. According to a report from the Valve Manufacturers Association (VMA), nearly 30% of valve failures result from incompatibility issues, which can lead to significant operational downtime and increased maintenance costs. Understanding the chemical properties of the fluids, such as pH, temperature, and viscosity, is essential for ensuring that the materials used in the ball valve can withstand the operating conditions without degrading.

Moreover, industry studies indicate that stainless steel exhibits excellent resistance to corrosion for a variety of applications, particularly those involving water, oil, and gas. However, certain aggressive media, including hydrochloric acid or sulfuric acid, may require additional considerations for valve selection due to the potential impact on the valve's integrity. For instance, using valves made from 316 stainless steel could provide enhanced resistance to these corrosive substances, as highlighted in a study published by the American Society of Mechanical Engineers. Thus, a thorough evaluation of the compatibility of fluids and media is vital for ensuring the longevity and reliability of your ball valve in the intended application.

When it comes to ensuring the longevity of stainless steel ball valves, proper maintenance is crucial. According to a report by the Valve Manufacturers Association, approximately 30% of valve failures are attributed to inadequate maintenance practices. Regular inspection and cleaning help prevent the buildup of debris and corrosion, which can compromise the valve's integrity and performance. It's advisable to check the valve seals and gaskets regularly, as wear and tear on these components can lead to leaks, impacting system efficiency and safety.

Additionally, lubrication plays a significant role in the maintenance of stainless steel ball valves. The American Society of Mechanical Engineers (ASME) suggests using appropriate lubricants to minimize friction and wear on the internal components. A well-lubricated valve not only operates more smoothly but also reduces the risk of seizing, which can halt operations in critical applications. Moreover, implementing a routine maintenance schedule, as recommended by industry professionals, can significantly extend the life of the valve and enhance its reliability, ultimately leading to reduced operational costs and downtime for businesses.

Additionally, lubrication plays a significant role in the maintenance of stainless steel ball valves. The American Society of Mechanical Engineers (ASME) suggests using appropriate lubricants to minimize friction and wear on the internal components. A well-lubricated valve not only operates more smoothly but also reduces the risk of seizing, which can halt operations in critical applications. Moreover, implementing a routine maintenance schedule, as recommended by industry professionals, can significantly extend the life of the valve and enhance its reliability, ultimately leading to reduced operational costs and downtime for businesses.