The selection of the appropriate pressure relief valve is crucial for ensuring safety and efficiency in various industrial applications. According to a recent report by MarketsandMarkets, the global pressure relief valve market is projected to reach USD 4.1 billion by 2025, growing at a CAGR of 5.6% from 2020 to 2025. This growth reflects the increasing adoption of pressure relief valves across industries such as oil and gas, chemicals, and pharmaceuticals, where the risk of overpressure can lead to catastrophic failures. Understanding the different types of pressure relief valves, their operational mechanisms, and the specific requirements of your industrial processes is essential for selecting the right valve that can withstand demanding environments and ensure compliance with safety regulations.

In this blog, we will explore the various factors to consider when choosing a pressure relief valve tailored to your unique industrial needs.

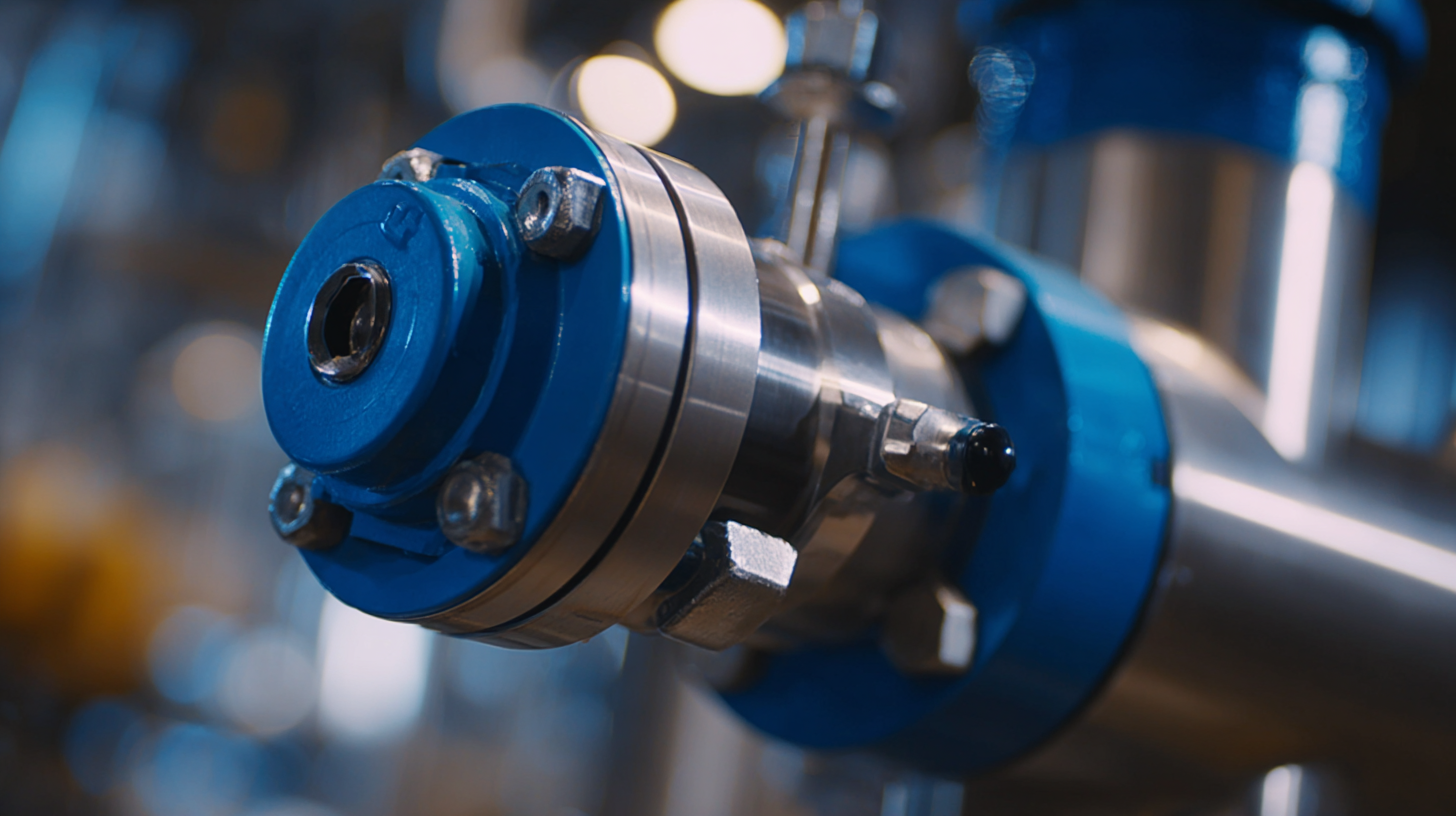

Pressure relief valves (PRVs) play a crucial role in ensuring the safety and efficiency of industrial systems. Their primary function is to prevent overpressure situations by automatically releasing excess pressure that could potentially lead to equipment failures or catastrophic accidents. By maintaining the pressure within safe limits, these valves safeguard both machinery and personnel, making them indispensable in various industries, including oil and gas, chemical processing, and manufacturing.

Pressure relief valves (PRVs) play a crucial role in ensuring the safety and efficiency of industrial systems. Their primary function is to prevent overpressure situations by automatically releasing excess pressure that could potentially lead to equipment failures or catastrophic accidents. By maintaining the pressure within safe limits, these valves safeguard both machinery and personnel, making them indispensable in various industries, including oil and gas, chemical processing, and manufacturing.

Understanding the importance of pressure relief valves goes beyond their basic operation. PRVs contribute to operational efficiency by allowing systems to function optimally under controlled pressure conditions. This regulation prevents energy losses and minimizes wear and tear on equipment, ultimately extending its lifespan. Additionally, compliance with industry standards and regulations mandates the use of reliable pressure relief systems, underscoring their significance in the design and operation of industrial facilities.

Proper selection, installation, and maintenance of PRVs are essential to uphold safety and efficiency, making them a critical consideration for any industrial operation.

When selecting a pressure relief valve for industrial applications, several key factors must be considered to ensure optimal performance and safety. First, understanding the application’s specific requirements is crucial. This includes knowing the maximum operating pressure, temperature ranges, and the type of media being handled, whether it be gas, liquid, or vapor. Each of these elements influences the valve’s design and function, playing a significant role in determining which valve will effectively protect your system.

Another important factor is the valve's set pressure and relief capacity. The set pressure is the point at which the valve will open to relieve excess pressure, and it should be accurately determined based on the system's design to prevent unintended activation or system failure. Additionally, the valve's capacity must match the potential pressure buildup to ensure it can relieve enough pressure quickly, safeguarding the system from hazards. By carefully considering these factors, you can choose a pressure relief valve that meets your industrial needs and enhances overall safety and efficiency.

When selecting a pressure relief valve (PRV) for industrial applications, understanding the various types and their specific functions is crucial. According to the Valves and Actuators Market report, the global demand for pressure relief valves is expected to reach $5.2 billion by 2026, driven by industries such as oil and gas, chemical processing, and power generation. Different types of PRVs, including spring-loaded, pilot-operated, and balanced-bellows valves, cater to distinct operational requirements. For instance, spring-loaded valves are ideal for lower pressure ranges, while pilot-operated valves excel in maintaining system integrity in high-pressure environments.

**Tip:** Always consider the valve's set pressure and its compatibility with the media it will regulate. A mismatch can lead to system failures or inefficiencies.

In addition to the type of valve, it's essential to look at application-specific requirements. For example, in the pharmaceutical industry, where contamination is a significant concern, using sanitary PRVs that comply with FDA regulations ensures safety and reliability. Meanwhile, the mining sector may benefit from heavy-duty PRVs designed to withstand harsh conditions and corrosive materials.

**Tip:** Utilize industry standards, such as ASME and API, as guidelines for selecting the right PRV to ensure compliance and performance efficacy.

| Valve Type | Application | Pressure Range | Material | Key Features |

|---|---|---|---|---|

| Spring-Loaded | Chemical Processing | 10 - 300 psi | Stainless Steel | High accuracy and reliability |

| Pilot-Operated | Oil & Gas | 50 - 1000 psi | Carbon Steel | Sensitive to pressure variations |

| Differential Pressure | Heat Exchangers | 5 - 150 psi | Titanium | Corrosion-resistant |

| Rupture Disc | Pharmaceuticals | 20 - 500 psi | Glass | Immediate response, no leakage |

| Electronic | Food Processing | 30 - 600 psi | Aluminum | Automated control for precision |

When selecting the right pressure relief valve (PRV) for industrial applications, careful evaluation of specifications such as pressure, temperature, and flow rate is crucial. For instance, recent advancements in chemical process designs underscore the importance of aligning PRV capabilities with system requirements. Specifically, in applications like chemical oxygen iodine lasers (COIL), managing the production of singlet oxygen involves intricate temperature and pressure dynamics, necessitating valves that can withstand extreme conditions while ensuring safety and efficiency.

Moreover, evaluating flow rate requirements is equally important in applications like seawater reverse osmosis (SWRO) desalination systems. An experimental investigation highlighted that variable feed flow rates and pressure conditions can significantly impact performance. For effective operation, the PRVs selected must accommodate operational fluctuations while maintaining optimal system integrity. Similarly, in biogas upgrading processes, where pressure swing adsorption is utilized, the pressure tolerance of the PRV is vital for achieving the desired carbon dioxide removal rates, ultimately ensuring the production of biomethane that meets pipeline quality standards. Therefore, a thorough understanding of these specifications not only ensures regulatory compliance but also enhances process reliability and efficiency across various industrial applications.

When it comes to maintaining and installing pressure relief valves (PRVs), following best practices is crucial for ensuring safety and operational efficiency. According to a report by the American Society of Mechanical Engineers (ASME), improper maintenance can lead to leaks or a complete failure of the valve, which in turn can cause catastrophic accidents. Therefore, regular inspections—typically every 6 to 12 months—should be conducted to check for signs of corrosion, wear, and tear.

Tip 1: Always ensure the PRV is properly sized for your system to avoid unnecessary stress and premature failure. Refer to industry guidelines which suggest using the manufacturer's sizing charts to select the appropriate valve based on your application's specific pressure and flow requirements.

In addition to routine inspections, proper installation is essential. Incorrect installation can obstruct the flow or prevent the valve from functioning effectively, potentially creating hazardous situations. A study by the National Board of Boiler and Pressure Vessel Inspectors indicates that over 30% of pressure relief valve failures arise from installation errors.

Tip 2: Install the valve in accordance with manufacturer specifications and industry standards, ensuring that all supporting structures are robust enough to handle the valve and the piping's dynamic forces. Regular training for maintenance personnel on installation standards can significantly reduce the risk of errors.