In the world of fluid control systems, the selection of the appropriate components is critical for optimal performance and reliability. Among these components, the spring loaded check valve plays a vital role in preventing backflow and ensuring unidirectional flow of fluids. According to a recent industry report by MarketsandMarkets, the global check valve market is projected to reach USD 2.32 billion by 2026, driven by an increasing demand for efficient fluid management in various industries, including oil and gas, water treatment, and pharmaceuticals.

As applications become more specialized and complex, understanding the key factors in selecting the right spring loaded check valve is crucial for engineers and procurement professionals. This guide aims to provide comprehensive insights into the criteria for choosing the ideal spring loaded check valve to meet specific operational needs and enhance system performance.

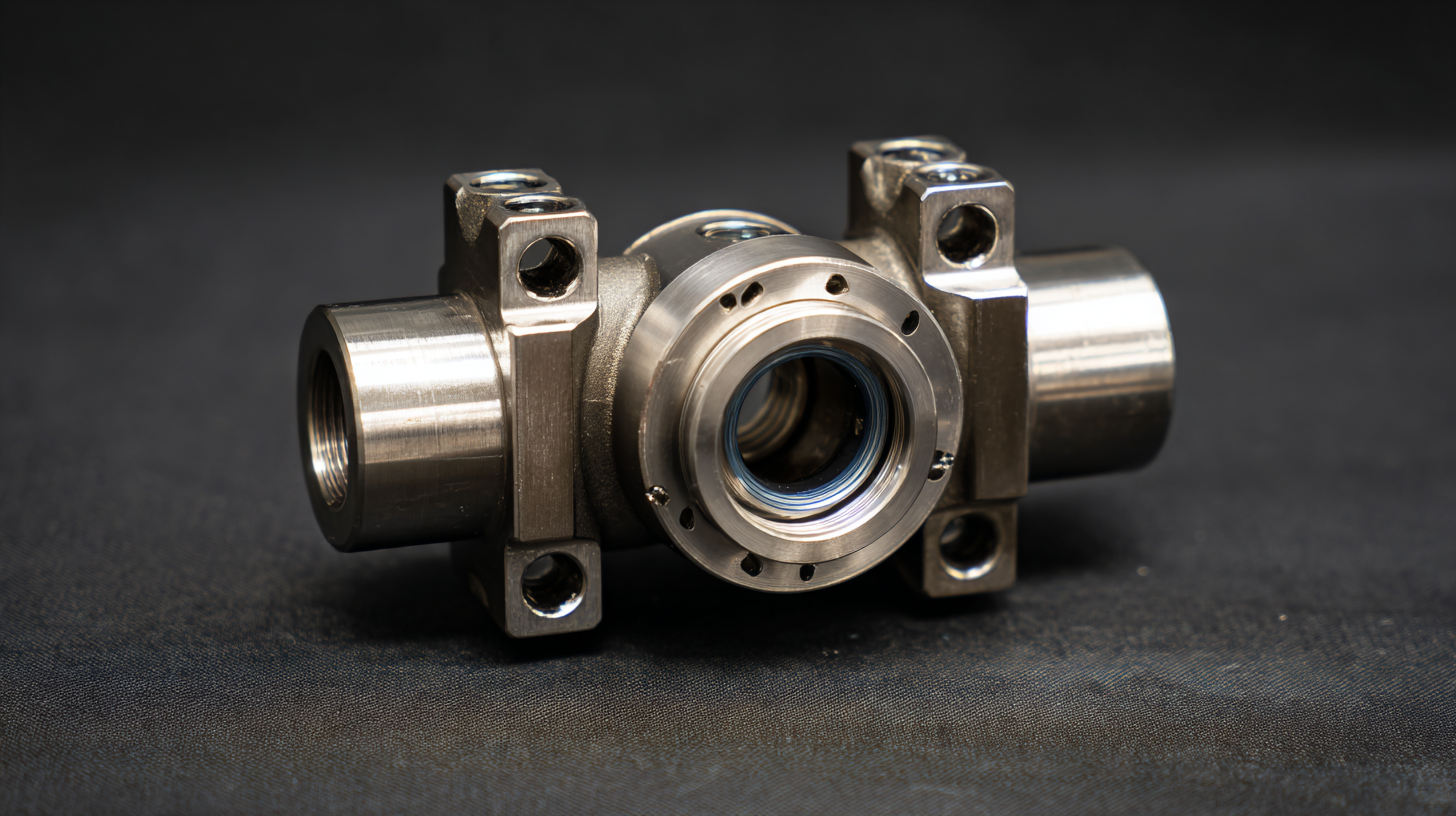

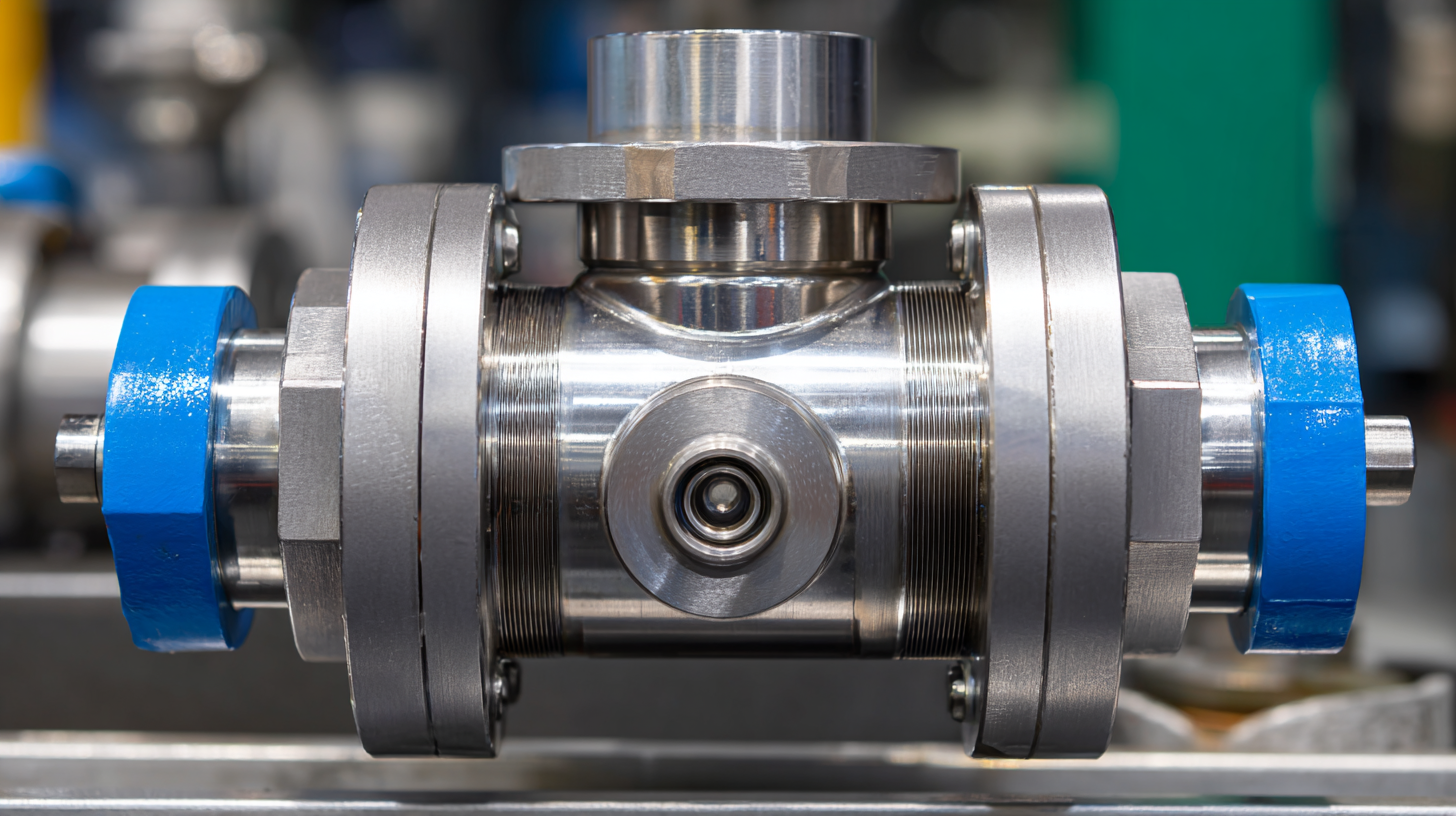

When selecting a spring loaded check valve for your applications, several key features should be taken into account to ensure optimal performance and reliability. First, consider the valve's material construction. The choice of material, such as stainless steel, brass, or plastic, significantly affects the valve's durability and resistance to corrosion. Depending on the fluid type and operating conditions, a robust material will enhance the lifespan of the valve and minimize maintenance.

Another crucial feature is the pressure and temperature rating of the valve. Make sure the valve can handle the operating conditions of your system without failure. Additionally, pay attention to the cracking pressure, which is the minimum upstream pressure required to open the valve. This specification is vital for maintaining proper flow and preventing backflow in your system. A valve with the right cracking pressure will ensure efficient operation while safeguarding your system against potential leaks.

Lastly, consider the size and flow rate capabilities of the valve. It should be appropriately sized to fit within your piping system and accommodate the flow rate needed for your application. A mismatched valve can lead to inefficiencies or even system damage. By carefully evaluating these key features—material, pressure ratings, and size—you can select a spring loaded check valve that meets your specific needs and enhances the overall functionality of your system.

When it comes to selecting the right spring loaded check valve, understanding its common applications is essential. These valves are frequently used in various industries, including water treatment, oil and gas, and HVAC systems. Their primary function is to prevent backflow, ensuring that fluids flow in one direction only, which is vital for the safety and efficiency of many devices and systems.

Tip: When considering a spring loaded check valve for your application, evaluate the media it will handle. Different materials and designs are suited for various fluids, from corrosive chemicals to high-temperature steam. Ensuring compatibility can prolong the valve's lifespan and enhance system performance.

Another common application is in pump systems where backflow could cause damage or downtime. In these scenarios, a properly selected spring loaded check valve not only protects the pump but also maintains operational integrity.

Tip: Always check the valve's pressure rating and flow capacity. A valve that is too small or insufficiently rated can lead to pressure drops or system failures, while an oversized valve may introduce unnecessary costs or complications to the design. Proper sizing ensures optimal functionality and reliability in the long run.

Selecting the right spring loaded check valve for your applications involves understanding how various factors can impact their performance. Among the critical elements are flow rate, pressure drop, material compatibility, installation orientation, and response time. According to the Valve Manufacturers Association, a well-chosen check valve can improve system efficiency by up to 25%, making it essential to consider these factors carefully.

Selecting the right spring loaded check valve for your applications involves understanding how various factors can impact their performance. Among the critical elements are flow rate, pressure drop, material compatibility, installation orientation, and response time. According to the Valve Manufacturers Association, a well-chosen check valve can improve system efficiency by up to 25%, making it essential to consider these factors carefully.

When evaluating flow rate, ensure that the valve you choose can handle the expected volume without obstruction. A valve that is too small can create undesirable backpressure and lead to premature wear or failure. Tip: Always refer to the manufacturer's flow rate data and select a valve that exceeds your maximum requirements to maintain optimal operational efficiency.

Pressure drop is another vital factor, as it affects the overall system performance. An excessive pressure drop can lead to energy loss and increased utility costs. Tip: Conduct a thorough analysis of your system's pressure requirements and consult industry reports indicating standard pressure drops across different valve types to guide your selection. By focusing on these critical factors, you can ensure a smoother and more efficient application of your spring loaded check valves.

When it comes to ensuring the optimal performance of spring loaded check valves, proper installation and maintenance are essential. First and foremost, before installing the check valve, it's crucial to ensure that the flow direction aligns with the valve's designation. This prevents backflow and potential damage to your system. Additionally, always inspect the valve for any debris or corrosion that could hinder its functionality. A clean and unobstructed pathway ensures that the valve operates smoothly and efficiently.

Once installed, regular maintenance checks are vital for the longevity of spring loaded check valves. Periodically inspect the valve for signs of wear or failure, particularly the spring mechanism which is responsible for the valve's operation. Lubrication may be necessary to maintain smooth movement, but be cautious to use a suitable lubricant that won’t harm the valve’s materials. Additionally, operational testing should be conducted regularly to ensure that the checks are functioning correctly and are able to handle the required pressure without leakage. By following these guidelines, you can maximize the efficiency and reliability of your spring loaded check valves in any application.

When selecting a spring-loaded check valve,

it's crucial to understand the various types available, as each is designed for specific applications and operating conditions.

Typically, these valves are classified into three main types: dual-disc, single-disc, and piston-style check valves.

The dual-disc check valves are favored for their ability to provide low-pressure drops and facilitate high flow rates,

making them ideal for use in fluid systems requiring efficiency and reliability.

Single-disc check valves, on the other hand, are simpler in design and are well-suited for applications with pulsed flow or varying pressure.

Their straightforward mechanism allows for easy maintenance while ensuring effective prevention of backflow.

Piston-style check valves, characterized by their use of a disc that moves vertically, offer excellent sealing capabilities

and are often employed in high-pressure and high-temperature applications. Understanding these distinctions allows engineers and project managers

to select the most appropriate check valve for their specific needs.