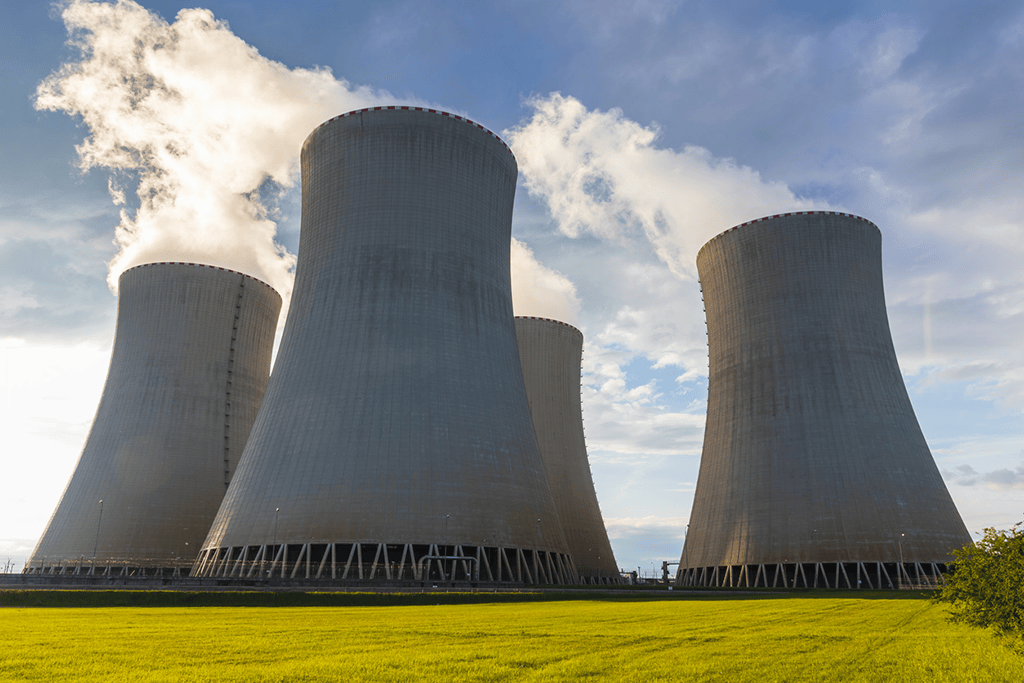

The milestone means IMI has provided valves for all four EPRs in operation worldwide. As well as Flamanville 3, IMI has supplied valves for use in Taishan 1 and 2 in China, and Olkiluoto 3 in Finland. It will also be supplying valves for use in the Hinkley Point C EPR currently under construction in the UK.

The 1,650 MWe Flamanville 3 reactor was connected to the grid on 21 December 2024 and features IMI Bopp and Reuther Main Steam Safety Valves, IMI TH Jansen Butterfly Valves, and a selection of products from the IMI CCI range, including Main Steam Relief Isolation Valves, Pressuriser Spray Valves, Main Feedwater Control Valves, and RIS/EVU Strainers—showcasing the depth of IMI’s nuclear capabilities. Engineers at the French site are working with French nuclear regulator, ASNR, to bring the reactor up to its full capacity, which it is expected to reach later in the year.

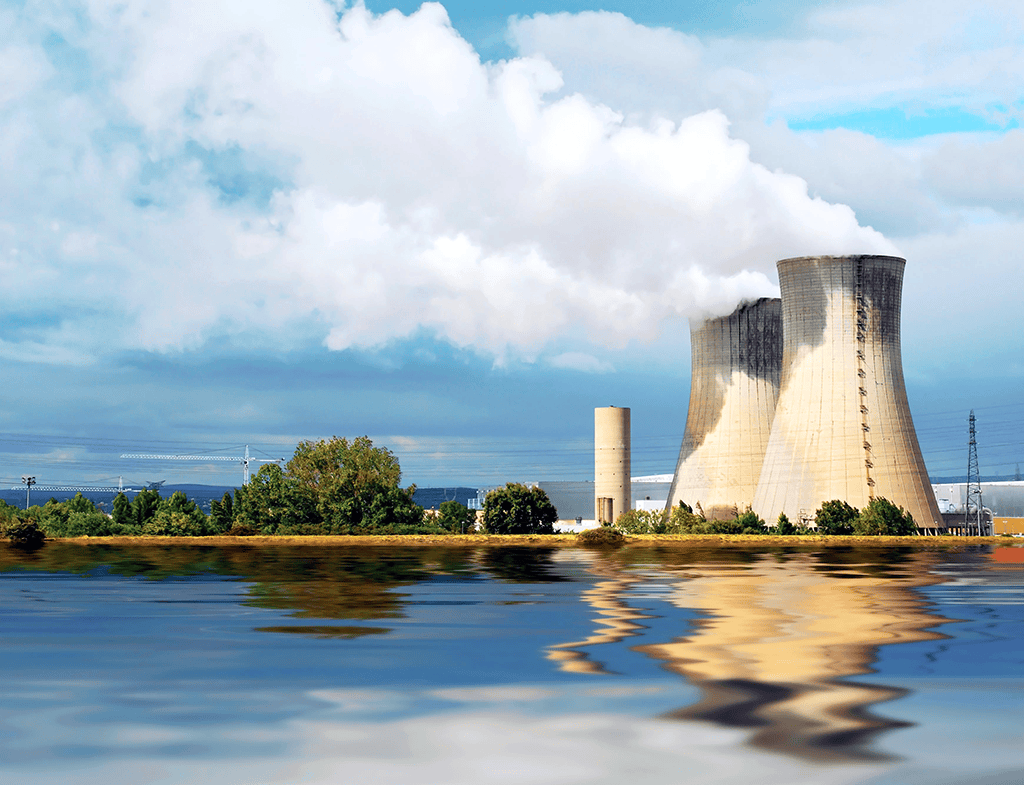

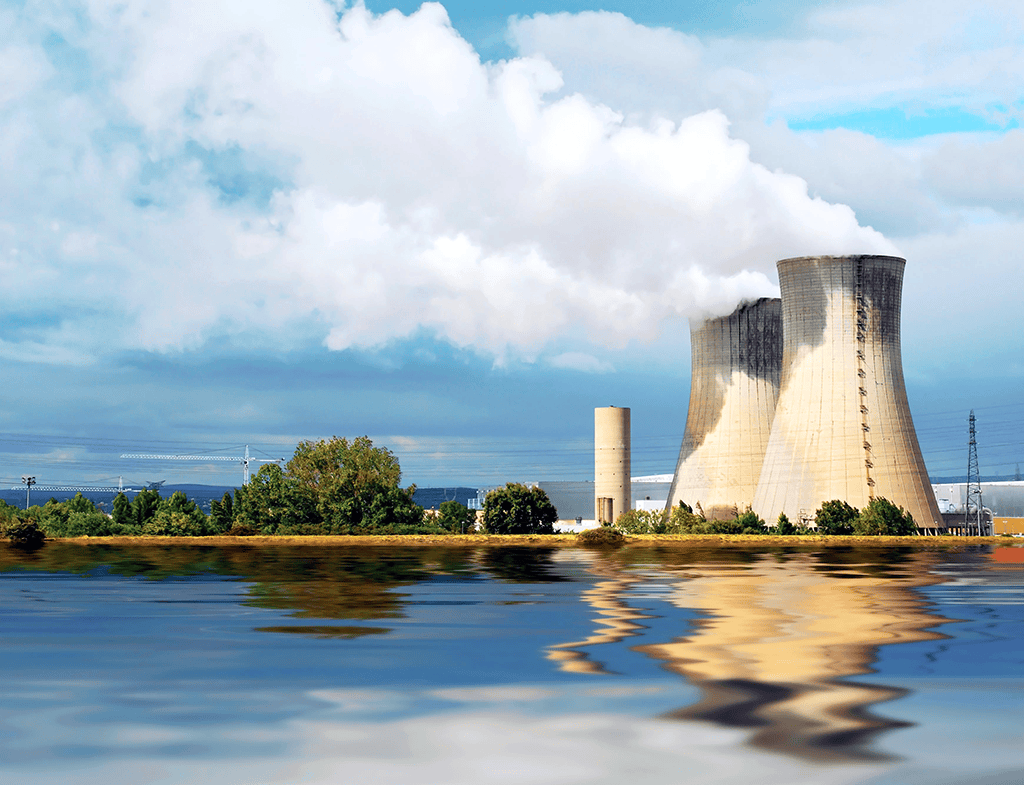

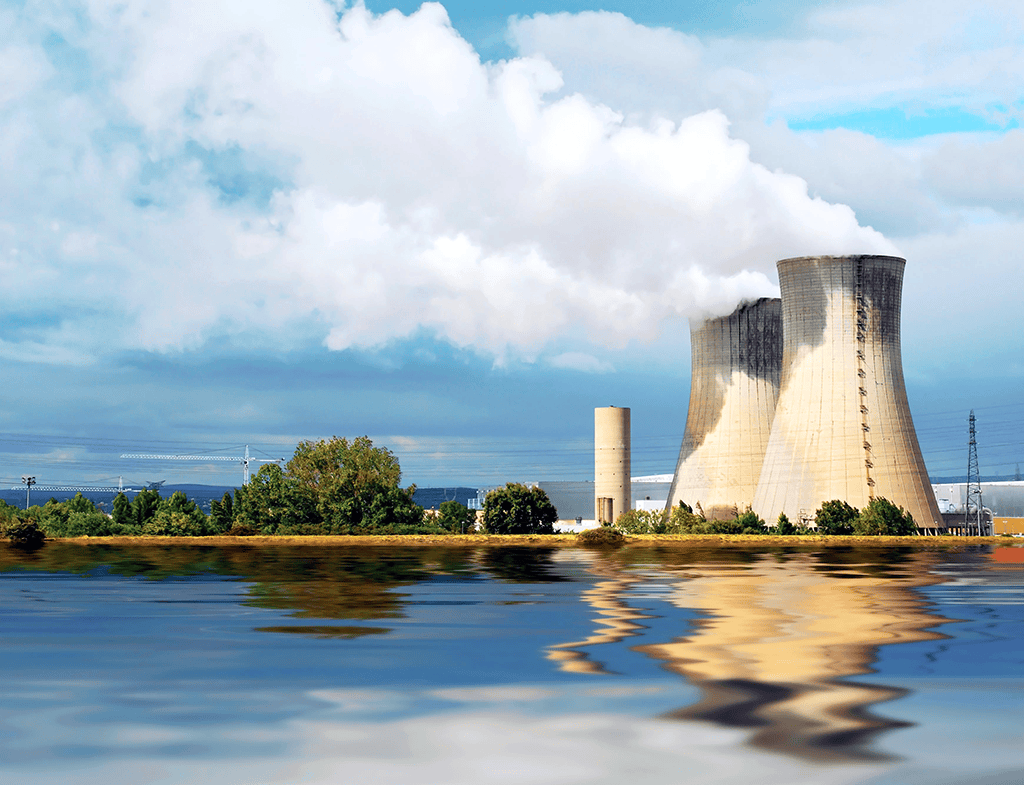

The EPR model is designed to offer a replicable design for efficient nuclear plants that use considerably less uranium than earlier reactor models. Flamanville 3 is now generating electricity for use across France’s national grid, while reducing radioactive waste by between 15% and 30% thanks to the more complete fission of uranium. The reactor will have an important role to play in achieving France’s goal of carbon neutrality by 2050.

Luc Todo, President of EMEA Strategic Projects Nuclear at IMI, said: “Nuclear plants are harsh environments where precise, robust and reliable equipment, manufactured to the highest standards, has a vital role to play.

“It speaks to the reputation of the IMI product brands involved that IMI equipment is in use across all EPRs worldwide and will be used at the forthcoming EPR at Hinckley Point C.”

IMI supports the nuclear power industry with valve technologies designed to ensure long-term safety, reliability, and performance. Our solutions help operators manage extreme conditions, reduce downtime, and meet strict regulatory standards.