Refineries face various challenges, such as controlling high pressures, managing multiple fluid types, preventing erosion and cavitation, reducing noise, and ensuring precise flow control. Refining facilities often have maintenance issues, space limitations, and stringent environmental regulations.

This case study demonstrates how IMI’s tailored valve technology helped a refinery in Bahrain overcome complex operational challenges.

Spotlight on the customer and end-user

Customer: A group of companies working on a major refinery upgrade project.

Location: A major oil refining facility in Bahrain.

The project is one of the largest refinery development projects in the Middle East. The refinery aimed to boost production from 265,000 barrels per day (BPD) to 360,000 BPD, a significant increase requiring high-performing, reliable equipment. However, it faced a number of significant challenges in achieving this aim.

The Challenges

The expansion project required the installation of over 2,000 valves for various critical applications, such as pressure and flow control of steam, crude oil, and diesel. The primary issues that the project team faced were:

The refinery’s inability to meet these operational requirements posed a potential threat to project timelines, forcing it to look for alternative solutions that could fulfil its rigorous demands.

The Solution

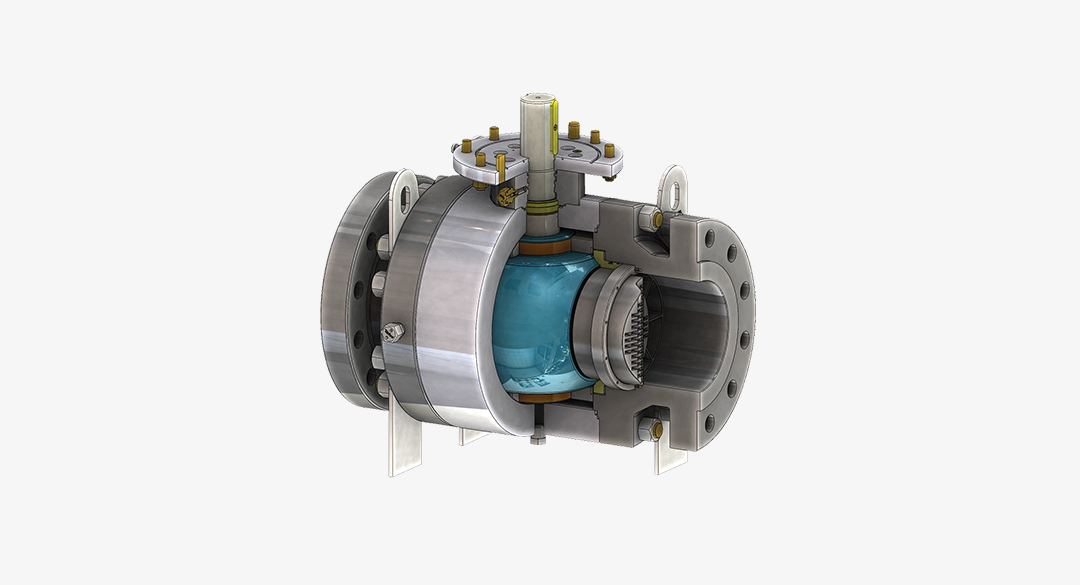

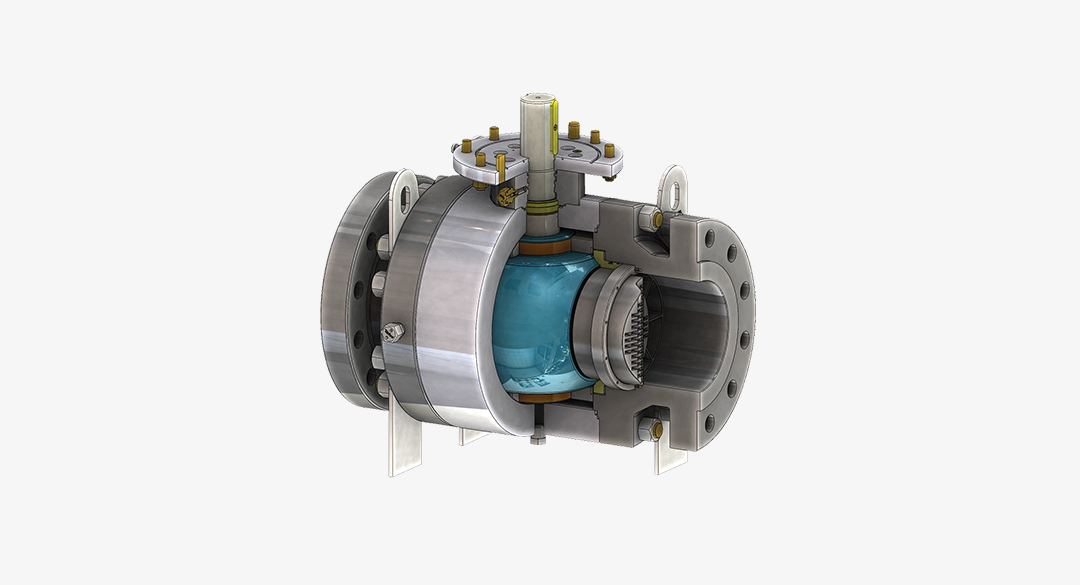

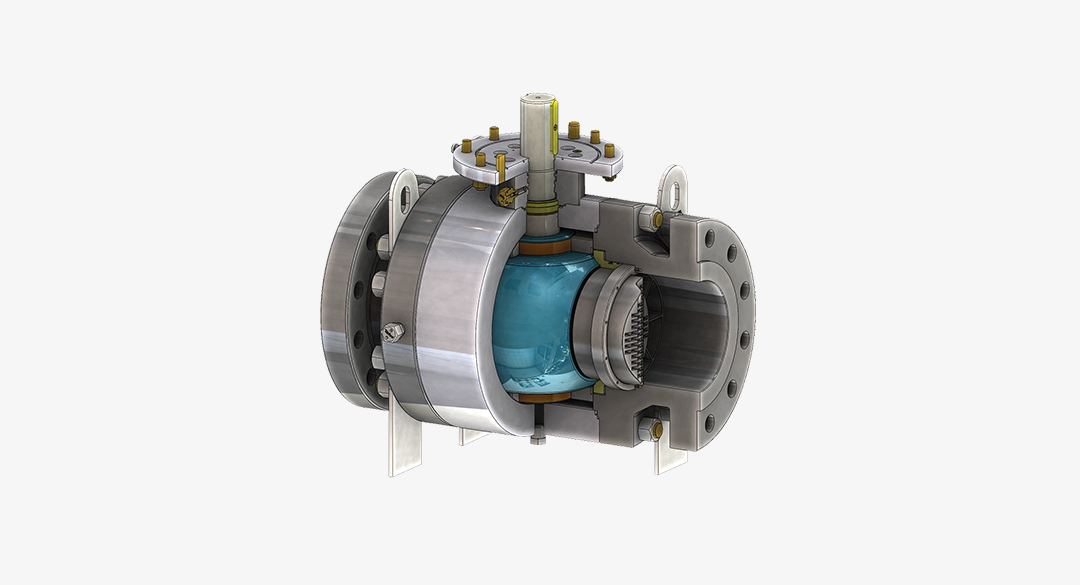

We introduced the refinery engineering team to our dBX Shield ball valve as the solution. Our team worked closely with the customer to discuss the benefits of transitioning from a globe to a ball valve. The team also demonstrated dBX Shield’s capabilities in meeting the customer’s operational goals. As a result, the customer accepted the dBX Shield solution.

Key outcomes

The implementation of dBX Shield brought significant improvements to refinery operations. Unlike the globe valves, which could not meet the minimum flow requirements, dBX Shield offered the following advantages:

This solution helped the refinery meet its expansion goals and set a new benchmark for efficient and cost-effective operations.

Refinery representative

Performance data/key statistics

While detailed performance metrics were not immediately available, ongoing operations have shown consistent noise reduction and reliable flow control with the dBX Shield valve. The facility in Bahrain continues to experience enhanced performance, reaffirming the long-term value of this solution.

dBX Shield is more than a solution; our cutting-edge technology can transform your refinery operations. It improves safety, efficiency, and cost-effectiveness in any high-demand environment by reducing noise, minimising vibration, and offering high rangeability.

If your refinery faces similar challenges, contact IMI today to learn how we can help you optimise your operations and achieve new performance levels.

Protect your plant with the dBX Shield – engineered to contain high-pressure leaks and prevent injury. Discover a simple, effective solution to enhance safety around valves in severe service environments.