DAM-B Steam Attemperator

Steam attemperator

Attemperation is the primary technique used for controlling the degree of superheat in a boiler or a Heat Recovery Steam Generator (HRSG). This is achieved through a controlled injection of water into the superheated steam. Attemperators are typically installed between superheater stages to regulate the output temperature of the boiler/HRSG, as well as protect any secondary superheater pipes from damage due to excessive heat.

The temperature controller for this attemperator, called inter-stage, regulates temperature based on input from a temperature transmitter placed on the boiler/HRSG output. A secondary attemperator, called final stage, is often installed after the inter-stage temperature transmitter in order to prevent thermal damage to the steam turbine during start-up. The final stage attemperator ensures that the steam temperature upstream of the turbine does not rise too fast.

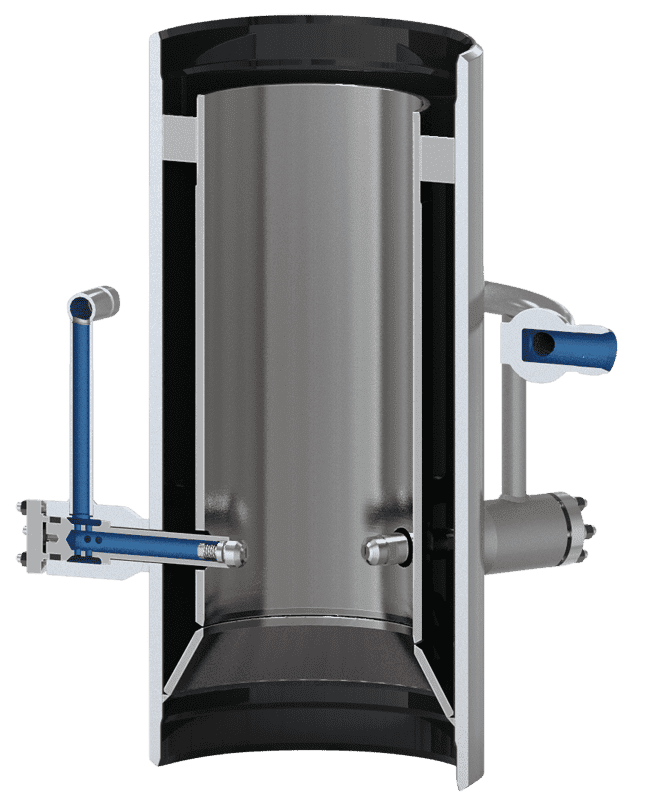

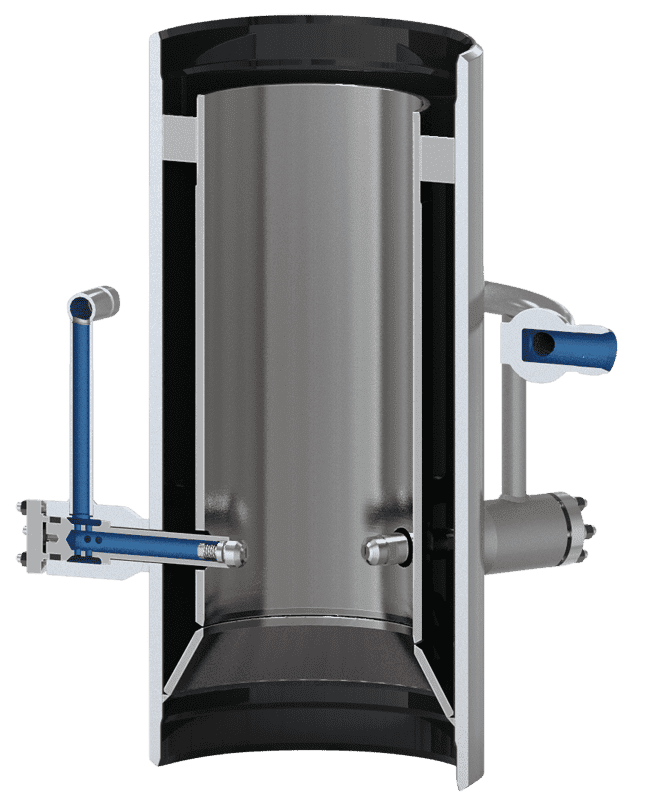

The DAM-B is a high-performing ring-style attemperator with a welded flow-profiling liner for superior evaporation and performance. It complies with all existing standards and is pressure tested on both the steam side as well as the water side.

The DAM-B attemperator is installed in the steam pipe with a number of water atomising nozzles attached. The size of the nozzles, their number, and insertion length vary depending on steam desuperheating needs and steam pipe diameter.

- The DAM-B can handle severe thermal cycling.

- The nozzles receive water from a common spray water pipe, distributing water evenly across the nozzles.

- Spray water flow is controlled by an external valve connected to the DAM-B water connection piece, which is regulated via a temperature control system.

- A welded flow profiling liner protects the steam pipe from thermal shock and erosion.

Product Specifications

Capacity

- Unlimited (Depends on size and number of orifices)

Pressure class

- DIN PN 16-320

- ANSI 150-2500

Materials

- Steam pipe material is adapted to connecting pipe material.

- Nozzles and springs are made from X19CrMoVNb11.1 as standard.

- Alternatively, nozzles and springs can be made available in inconel, suitable for high temperature applications and conditions without water injection.

Rangeability

- Nozzle turndown: Limited only by turndown of selected water control valve.

- System turndown: Minimum steam velocity depends on pressure, temperature and superheat, but should typically not be below 6-8 m/s (20-25 ft/s).

Find your perfect flow control solution