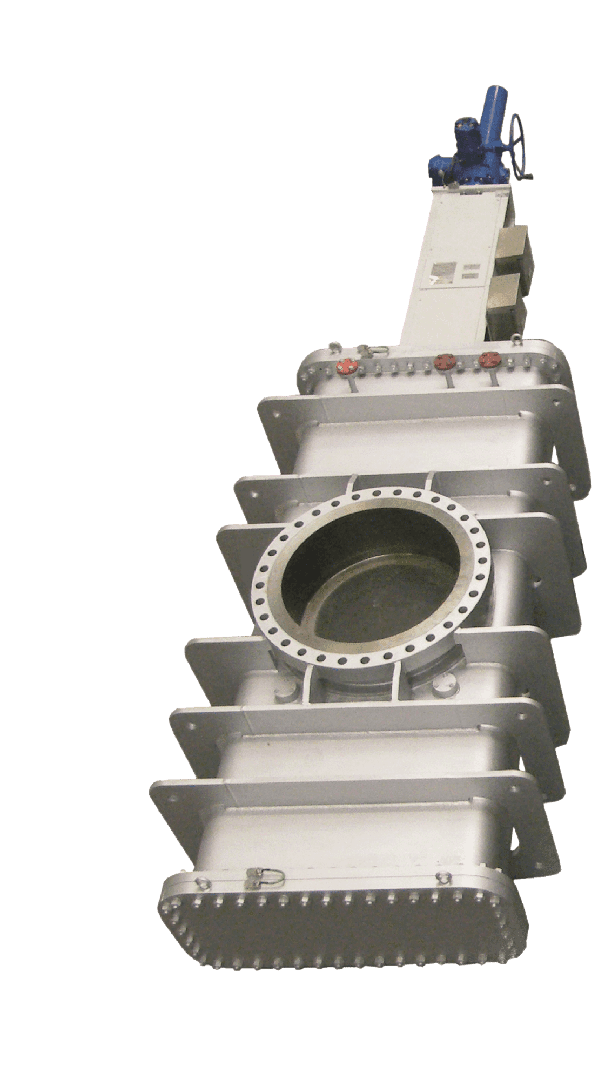

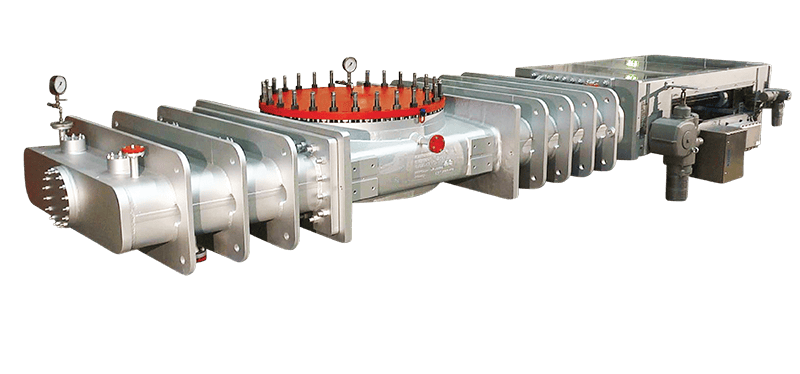

Delayed Coking Bottom Unheading – Compact Design

Optimised and reliable unheading solution for Delayed Coking Units

IMI Z&J’s Delayed Coking Bottom Unheading Device is engineered with a compact design, offering safe, robust, and reliable performance for critical operations in Delayed Coking Units (DCUs). With a fully automated system based on proven double disc gate valve technology, this solution ensures high operational efficiency while reducing maintenance and energy costs.

- Compact valve body: Smaller face-to-face dimensions and reduced weight for easier integration into space-constrained setups.

- Double block and purge: Two independent discs ensure true double block and purge, maximising sealing integrity and safety.

- Low steam consumption: Designed for energy savings, with minimal steam use for better environmental and cost performance.

- Corrosion & wear resistant: Hard-faced seats protect against wear, ensuring long-lasting performance even in harsh conditions.

- Simplified maintenance: Easy inspection access and minimal spare parts requirements reduce downtime and keep maintenance costs low.

Dimensions

- L 9.5 m x W 2.56 m x H 0.79 m (L 374″ x W 101″ x H 31″)

Weight

- 40,000 kg (88,000 lbs)

Actuator types

- Electric or hydraulic options available</li

Purge media

- Steam

Operating temperature:

- -40°C to +60°C (-40°F to 140°F)

Leakage rate

- API 598 compliant

Find your perfect flow control solution