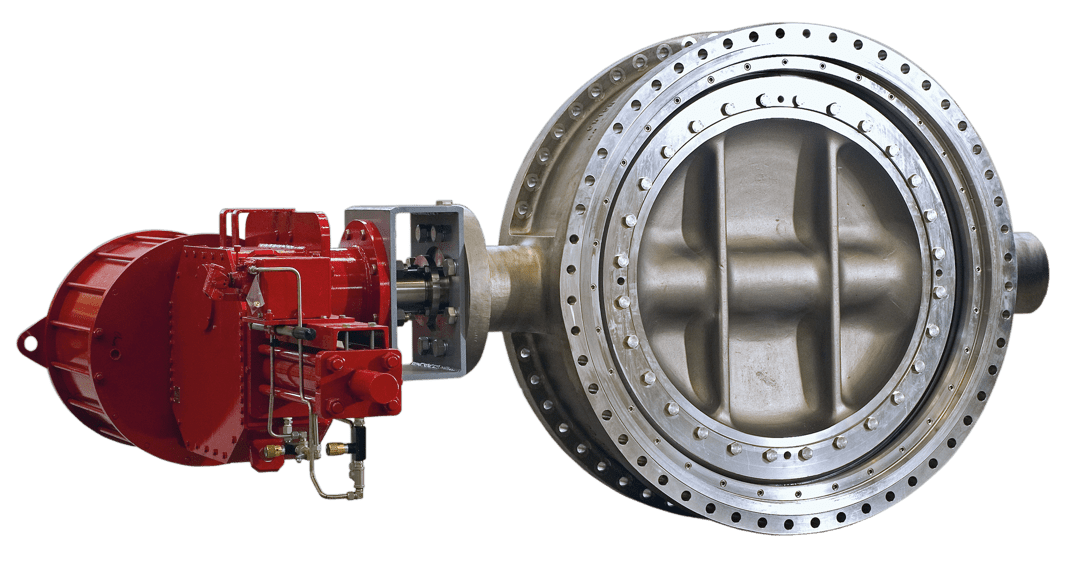

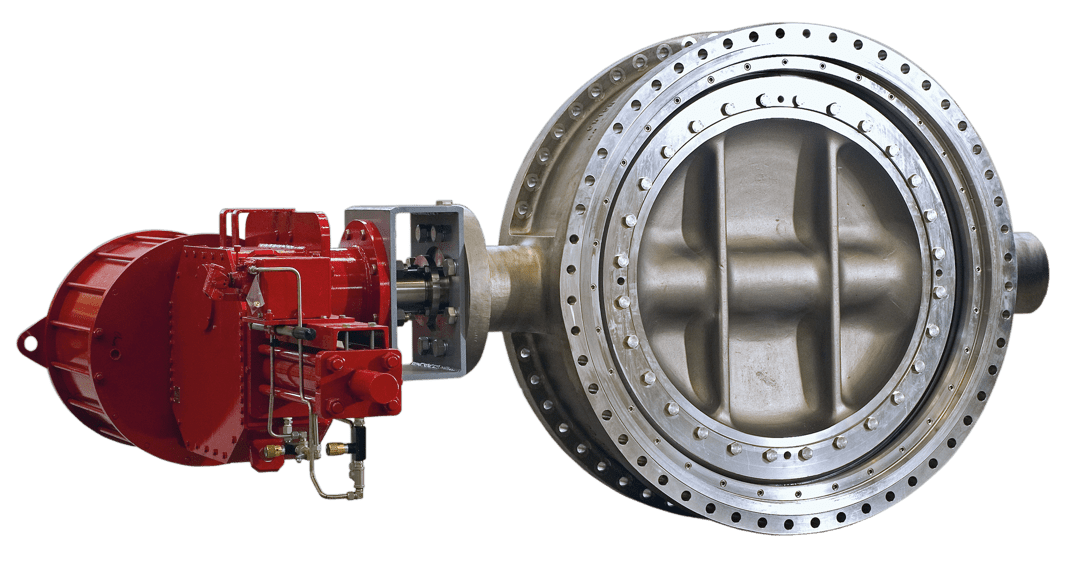

MV Triple Eccentric Metal Seated Butterfly Valve

Customers around the world choose our MV Series valves for their unmatched combination of control, reliability, and compact design. These valves are perfectly suited for critical applications requiring high pressure, tight shut-off, high temperature, or cryogenic performance, as well as throttling and isolation duties.

- Resilient metal-to-metal seal for durable, leak-free performance.

- Full metal construction ensures longevity in extreme environments.

- Zero leakage bi-directional tight shut-off for optimal sealing in both directions.

- Quarter-turn friction-free operation reduces torque and energy consumption.

- Fire-safe and fire-tested to meet stringent safety standards.

- Integral external position indicator on valve shaft and body for precise operation.

- Wide range of materials and sizes to fit diverse applications.

- Triple eccentric design minimizes wear and extends service life.

- External anti-blowout device for enhanced safety and reliability.

Product Specifications

Materials

- WCB

- CF8M, CF3M

- LCB, LCC, LC3

- Duplex

- Superduplex

- Monel

- Hastelloy

- 254 SMO

- Alloy steel WC6, WC9

- Inconel

- Alloy 20

- Aluminium bronze

- Titanium

- C5, C12

Body styles

- See brochure

Nominal Diameter Range

- DN 2″ to 160″

Temperature limits

- From -254°C (-425°F) to +818°C (+1600°F)

Pressure limits

- From full vacuum to 430 bar (6250 psi)

Applicable standards

- Design: ANSI B16.34/ ASME VIII/ API 609

- Face to face: API 609/ ISO 5752

- Double flanged connection: B16.5/ B16.47/ASME VIII/ DIN/ ISO

- Fire test: BS 6755–API607-ISO FDIS 10497

- Fugitive emission: ISO 150484-1

- Testing: API 598

Rating

- NP 6 – 10 – 16 – 25

- ANSI CI.150 – 300 – 600 – 900 – 1500 – 2500

Find your perfect flow control solution