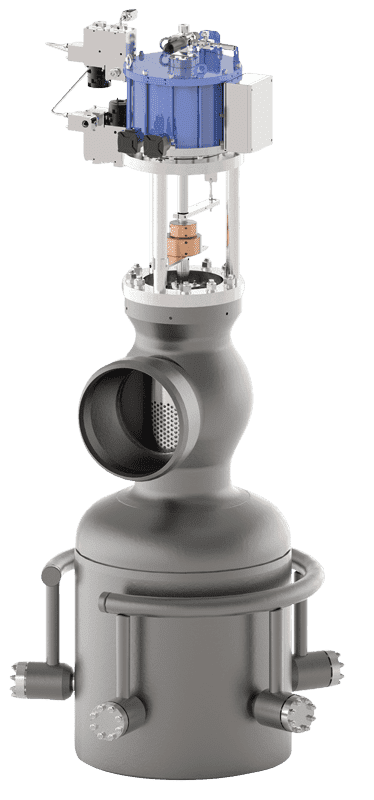

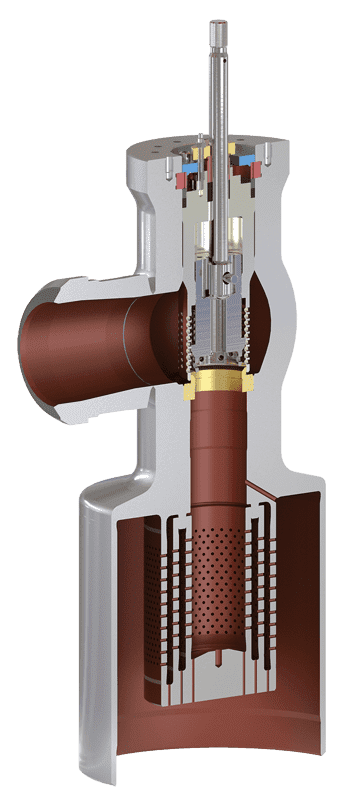

VLR Pressure Reducing Valve

High-performance steam pressure control for severe conditions

The VLR pressure reducing valve is designed for high and low-pressure steam turbine systems. It is commonly used in applications where excess steam is vented to the atmosphere during load rejection, helping manage high steam flow until the firing rate is adjusted. The valve splits the pressure drop between the valve itself and a downstream diffuser or silencer, reducing noise. It is also suitable for general pressure control applications where desuperheating is required, and can be combined with a downstream desuperheater to emulate steam conditioning functions.

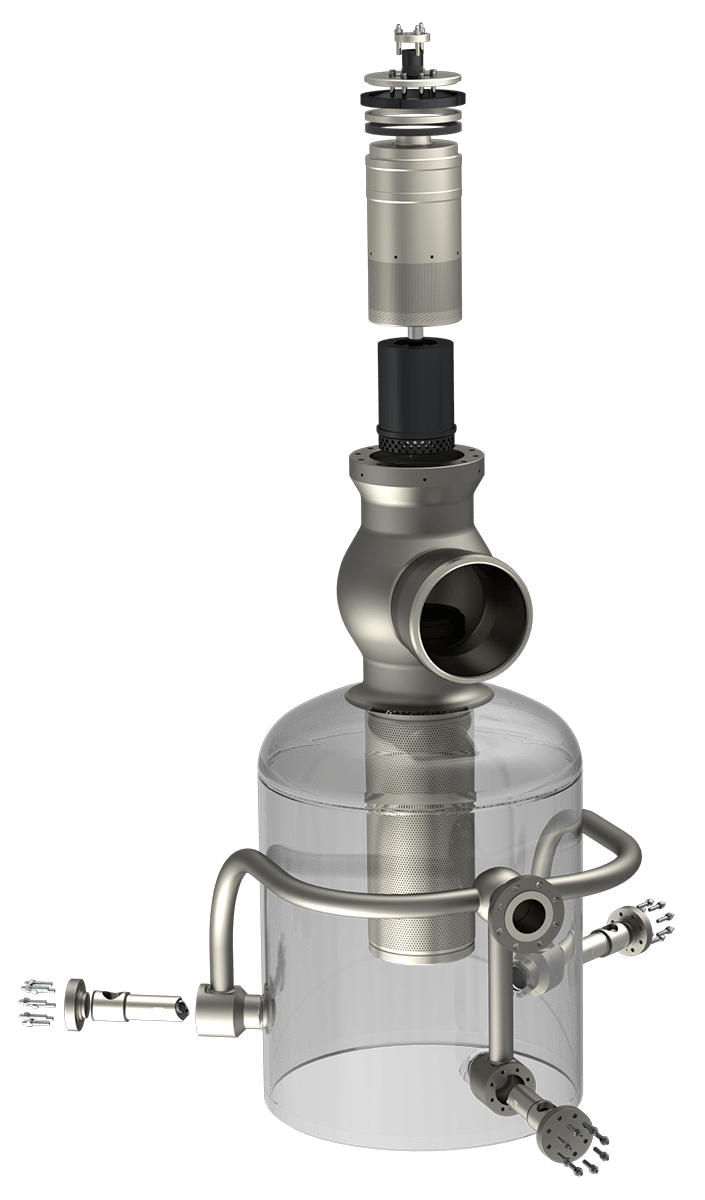

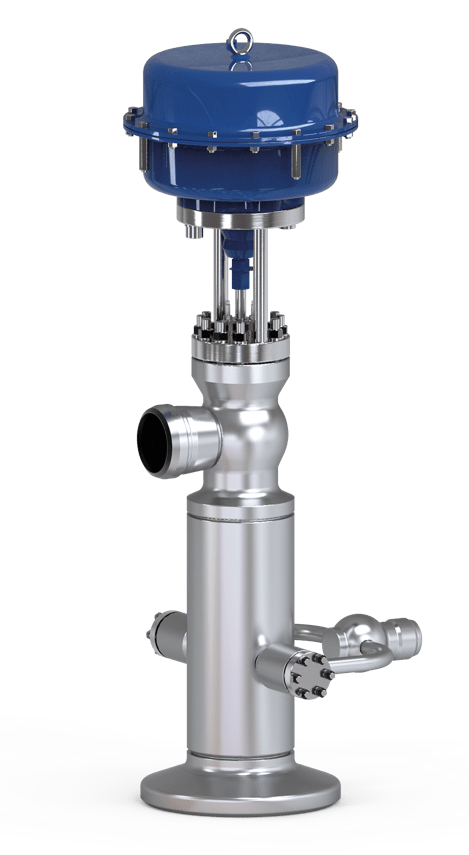

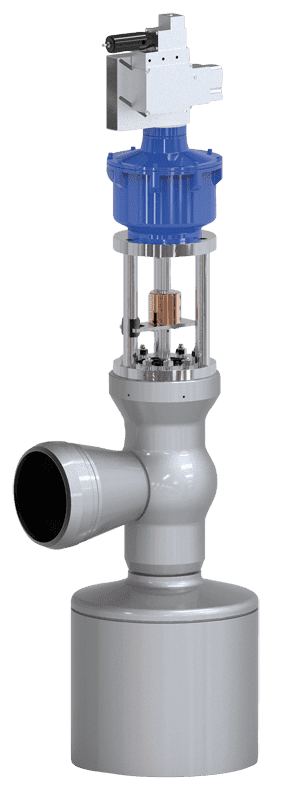

- Extended drilled bonnet design to optimise steam pressure control and prevent rotation forces caused by steam flow.

- Cage-type plug with multiple drilled holes for effective steam pressure throttling.

- Homogeneous forged body minimising thermal stress, ensuring durability in extreme conditions.

- Pressure seal bonnet providing tight sealing and easy access for maintenance.

- Customisable inlet and outlet connections to suit different system requirements.

- Available in a balanced tight design, reducing the opening forces required.

Product Specifications

Valve sizes

- 20 – 400 mm seat diameter

(other sizes available on request)

Leakage class

- B: ANSI Class IV FCI 70-2 / EN 1349

- BTC / TC: ANSI Class V FCI 70-2 / EN 1349

Rangeability

- 50:1

SIL classification

- SIL level up to 3 achievable for both quick open and quick close, depending on system configuration.

Materials

- Forged materials adapted to match the connecting pipe material for optimal performance and durability.

Find your perfect flow control solution