Many of our existing solutions also continued to enjoy increased adoption in industrial plants and facilities worldwide. And we as an organisation continued to embrace inclusion and diversity and participated in a number of key global events. So, let’s look back on 2023 and the highlights from this eventful year.

The launch of our 840-3D and 860-3D control valve makes a further contribution to the elimination of erosion, vibration and noise in today’s oil and gas, power generation and nuclear facilities. Manufactured using advanced techniques, the 840-3D / 860-3D valve is made from highly customised 3D printed trim. Taking multi-path, multi-stage, low noise DRAG® technology to a new level, the valve provides optimum control with great rangeability. While minimising the losses created by valve leakage, it delivers optimum process performance and is a significant addition to our well-established 840 series.

With the demand for renewable energy rising exponentially, non-dispatchable renewables are becoming a larger component of the energy mix. Optimised for use in high-cycling combined cycle power plants, the new VLB3 turbine bypass valve is designed to handle the higher cycling demands characteristic of gas-fired power plants. So, with the energy sector being driven by decarbonisation, digitalisation, and decentralisation, the VLB3 will help our customers maximise plant uptime, performance, and efficiency.

This autumn marked the successful launch of our new steam trap monitoring solution. Steam trap leakage generates major problems for site engineers. It increases the likelihood of unplanned plant shutdowns while also generating significant reductions in waste and CO2 emissions. The new steam trap monitoring solution features smart software that communicates with first generation STM-10 sensors by way of long-range wireless technology like LoRaWAN, helping customers to anticipate and reduce failure, while also reducing plant operating costs.

Fitted with one of the most advanced positioning algorithms currently available, our new Smart High-Performance Positioner (SHP) is able to anticipate and mitigate any operational challenges. Designed and manufactured at IMI STI’s facilities in Levate, Italy, the SHP Positioner ensures that all valve-controlled processes operate safely and efficiently and supports high-speed performance in large-volume actuators. It also offers real-time insights, which will prove vital in implementing efficient preventative maintenance that reduces costs and downtime.

Adoption of our EroSolve Wet Steam solution has continued to increase throughout 2023 as our customers appreciate its value in reducing steam leakage in energy production facilities. The solution’s success in tackling the effects of valve steam leakage such as erosion, water hammer, excessive noise and vibration has proven resounding, and has generated significant benefits in the power generation industry. Following successful installation in one Indian power plant the solution extended the life of the control valves against wet steam erosion and avoided the burning of 7500 tonnes of additional coal. Not only did this result in an annual saving of £250,000 per valve, but also prevented 10,000 tonnes of CO2 from entering the atmosphere.

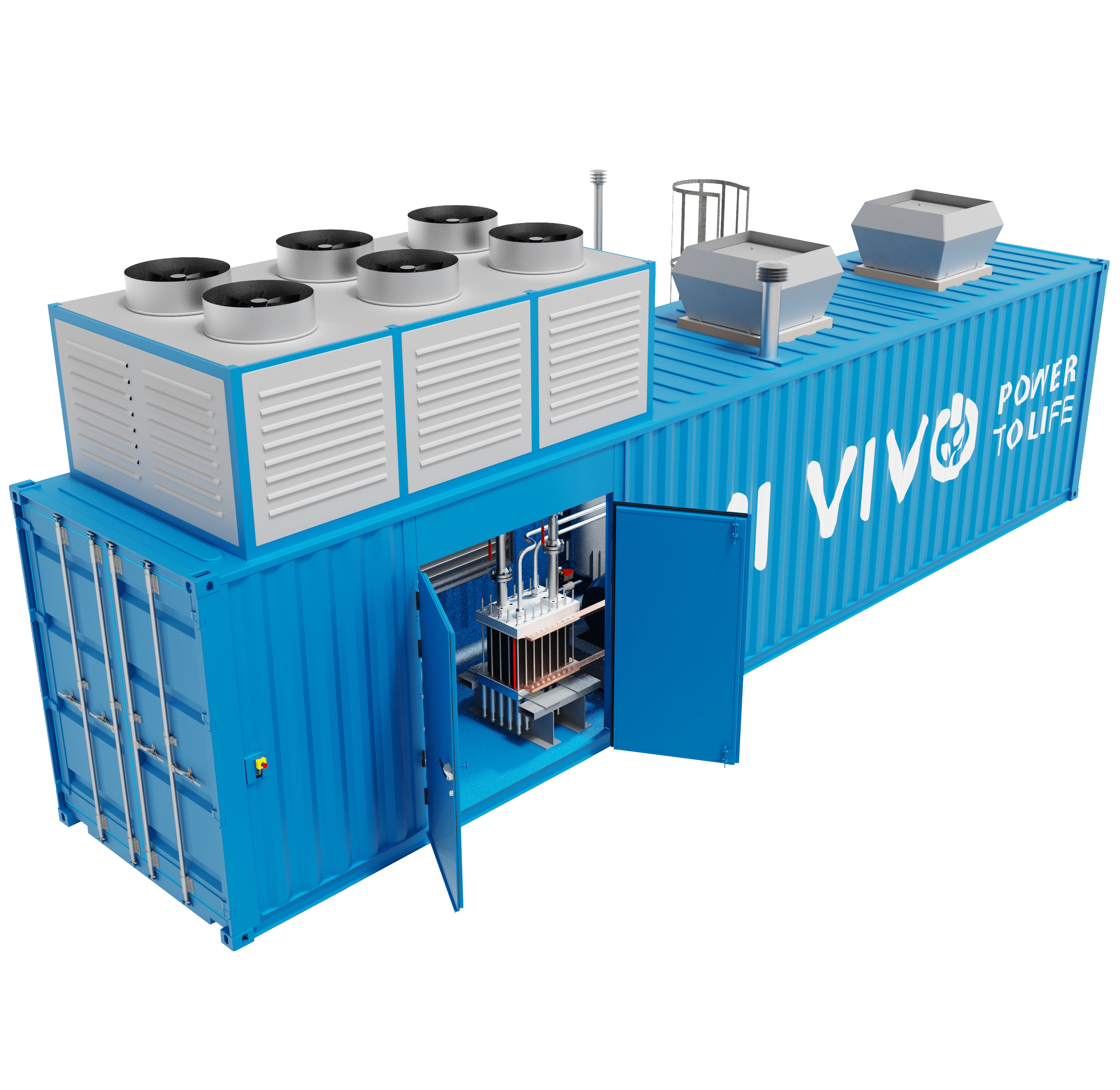

This year, we continued to invest in breakthrough engineering for the green hydrogen production sector with a further two Proton Exchange Membrane (PEM) electrolysers being commissioned by UK and European research institutions. The team at IMI VIVO in Sardinia have also developed a real-time digital dashboard that monitors the electrolyser’s performance and is available for PCs, Macs, tablets, and smartphones which means you can monitor electrolyser performance 24/7 and from any location.

This year’s activities schedule proved to be as busy as ever, with colleagues from across IMI participating in Birmingham Pride, Menopause Day, World Mental Health Day, and IMI Way Day. As ever, we continued our programme of outreach activities with the aim of inspiring the next generation of engineering talent, and again welcomed a new cohort of IMI graduates into our community.

The coming year will no doubt bring further rewards, further challenges, and its share

of success for IMI. We can be confident that we have outstanding talent at all levels of our organisation, and that will continue to innovate, grow, and flourish.

Wherever you are and however you celebrate this festive period, we wish you and your family a very happy holiday season and look forward to working with you in delivering more breakthrough engineering for a better world in 2024.