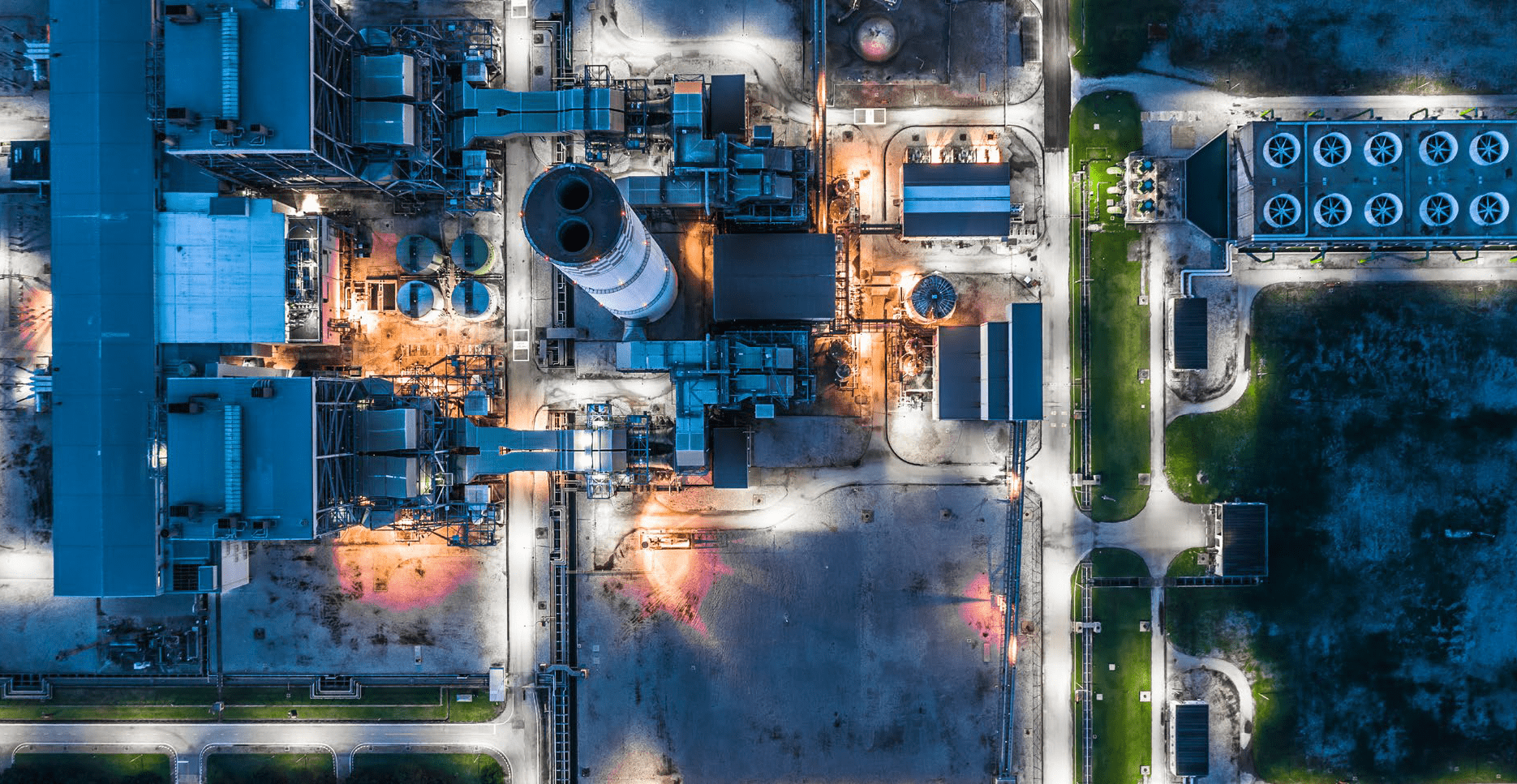

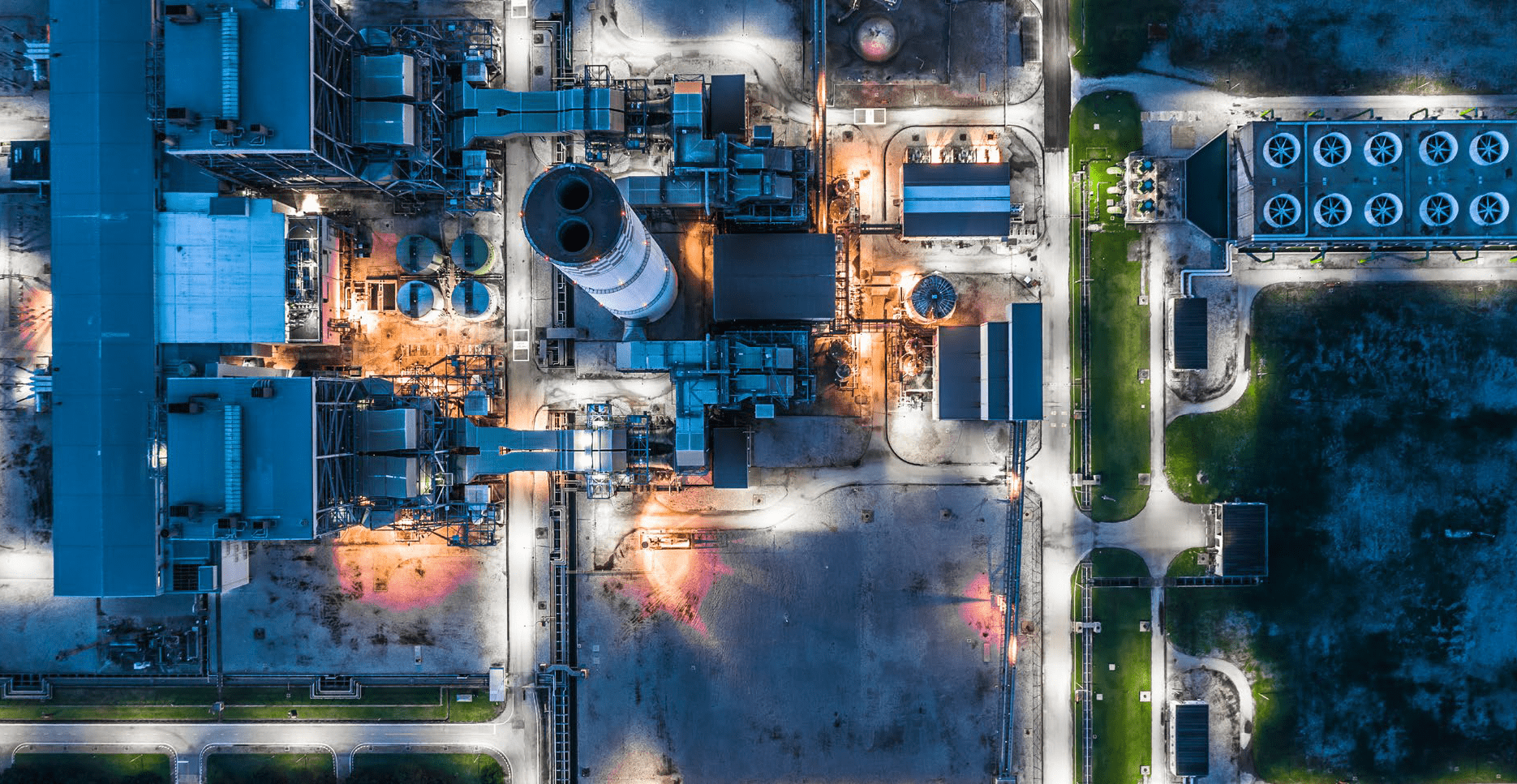

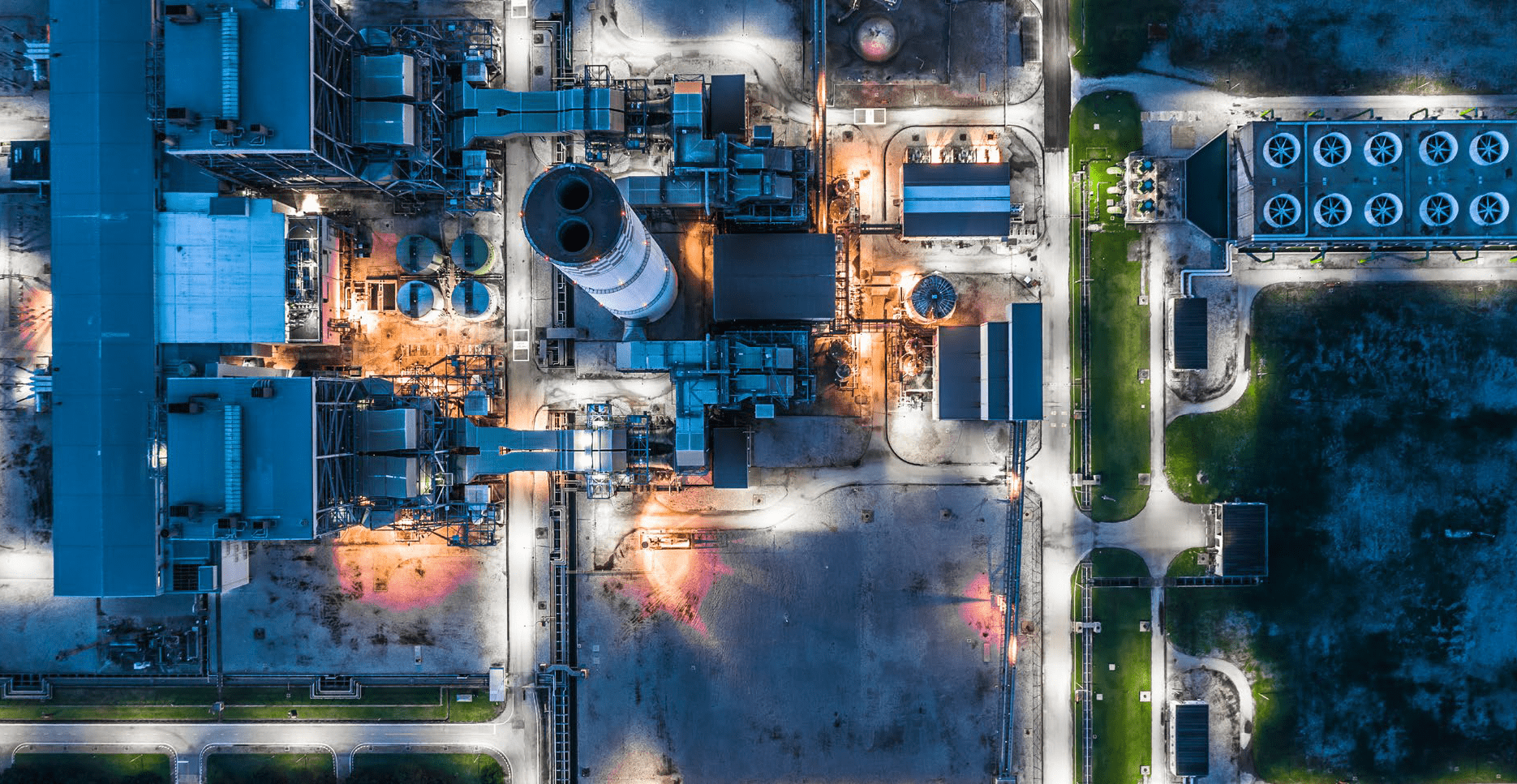

A combined cycle, natural gas power plant located in the Midwest had competitor temperature control valves and probe style attemperators installed since 2001 when the plant was commissioned. The configuration at the plant is typical of the early 2000’s with an HRSG utilising three high pressure (HP) steam attemperators and one reheat (RH) attemperator per unit. The plant sat stagnant for several years as a mothballed plant and has since been fired back up. Due to the high cycling demand over the last couple years, the plant has been forced to keep these attemperators at the top of their maintenance list and have stated that the valves require frequent (every other month) rebuilds due to broken probe assemblies. Broken valve/probe components in interstage attemperators cause water leakage, cracking of steam pipe, poor temperature control, and probe attemperator stem and nozzle breakage. These attemperator issues lead to poor plant reliability and operation.

IMI DA-90DSV

IMI CCI has a long history of solving attemperator issues at customer sites and installing more effective attemperator designs. The DA-90DSV design was developed as a direct replacement to competitor designs with minimum pipe modifications.

Key features of the DA-90DSV are lightweight cast body, Class V shut-off, graphite stem packing, forged design, no trim in steam flow, tapered profile to minimise flow induced vibration, and variable spray nozzle.

IMI CCI has over 200 DA-90DSV’s installed in North America, at over 50 combined cycle power plants. Roughly 90% or more of these have replaced the standard competitor probes that had been installed. The DA-90DSV was the perfect solution for this customer’s issues. The customer will not only benefit from the reduced maintenance intervals but also the significantly reduced man hours needed during planned and unplanned outages as well as having sufficient spare parts on hand. This valve will provide better control of their steam operating system making the plant more efficient and reducing water consumption.

IMI CCI won the opportunity to sell the upgrade and have proven once again that IMI CCI provides an unbeatable solution.