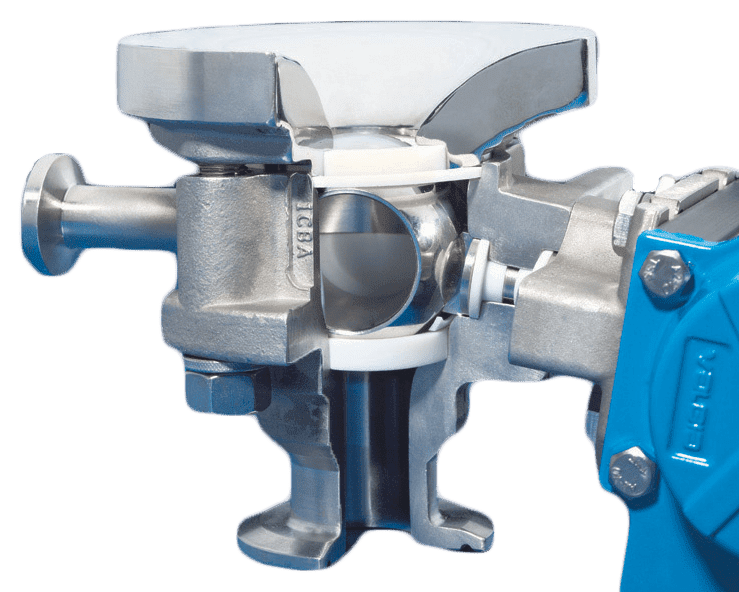

Igenix® Two-way Ball Valves – Tank Bottom

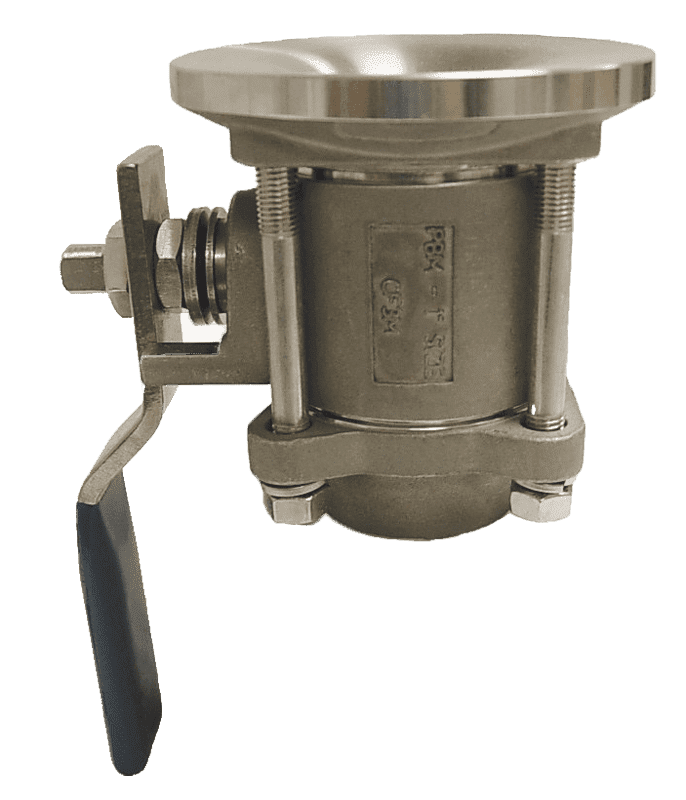

Tank Bottom Series 9 Cast/Forged Series 8 , 1/2”- 6”

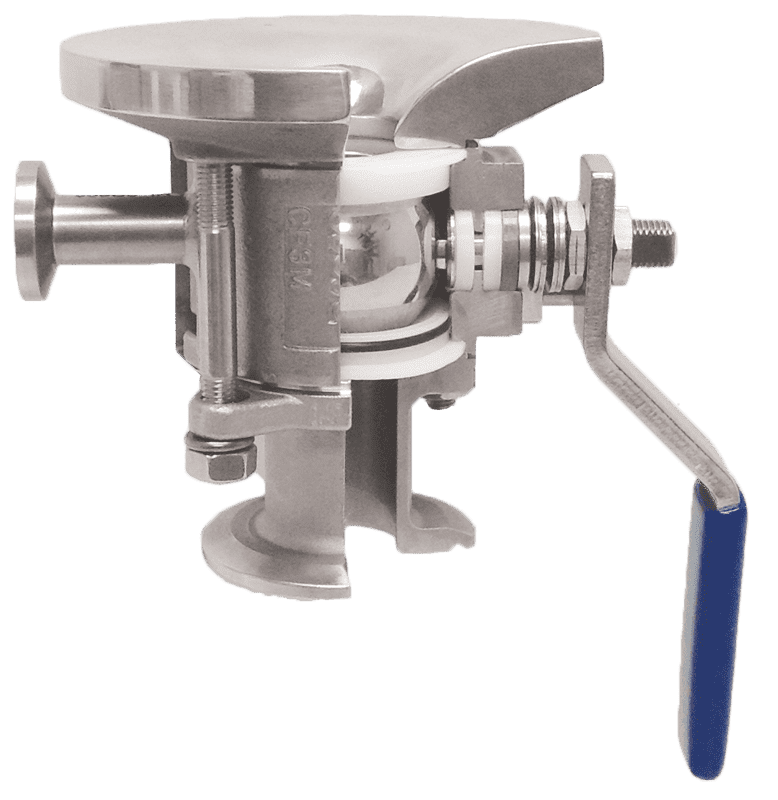

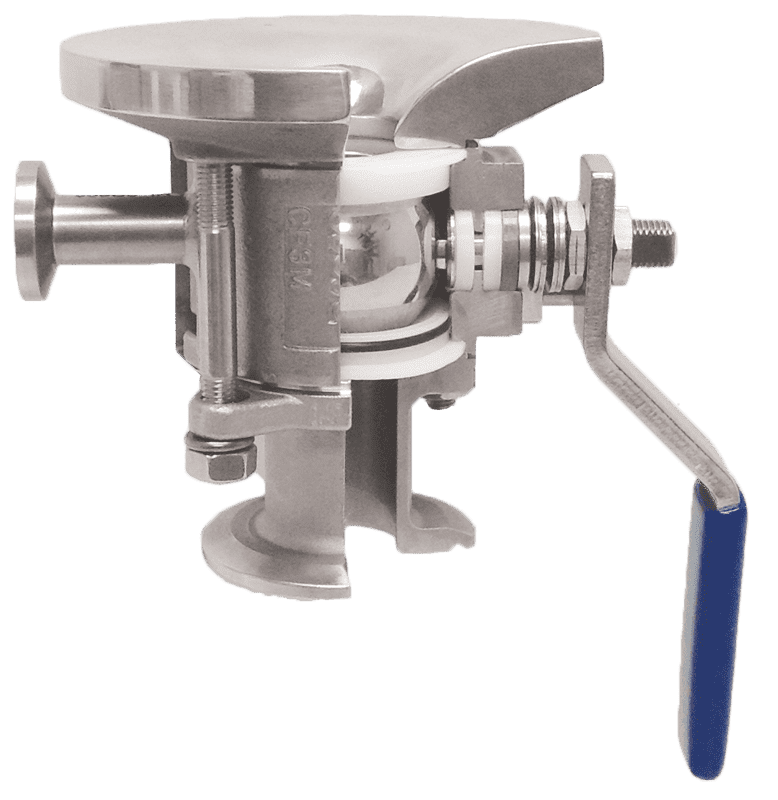

Two-Way Tank Bottom valves are suited for sanitary tank, vessel, and reactor applications. Angle Stem Flush Tank Bottom valves provide actuator clearance on jacketed or insulated vessels.

- Unique Adjust-O-Seal® feature allows in-line valve adjustment to compensate for normal wear on valve seats. Note: FI Series Tank Bottom DO NOT have have o-rings.

- Pad radius facilitates efficient drainage and reduces the pocket area above the ball.

- Upstream and downstream bubble-tight sealing capability allows valve body cleaning, purging, and draining.

- Stem assembly accommodates IMI PBM Direct Mount Actuation for accurate alignment and increased cycling life.

- Forged and cast valves are low-controlled ferrite.

- True-Bore® (valve bore same as connecting tubing) – no puddling.

- ASME BPE compliant.

- Available in Angle Stem versions for applications where automation may interfere with tank head or jacket.

- Valves are rated to full vacuum.

- Certified Material Test Report (CMTRS) provided for wetted components.

Product Specifications

Sizes

- 1/2” – 6” series 9

- 1/2” – 4” series 8

Material

- 316L

- Low ferrite cast and forged

- Hastelloy™

- AL6XN™

Temperatures

- Ambient for V-TEF™ to 400°F

- S-TEF® to 450°F

End connections

- Extended tube

- Hygienic clamp

- Compression ends (1/2” – 1”)

Seats & seals

- White V-TEF™ standard

Stem packing material

- V-TEF™ and S-TEF®

Body bolts & nuts

- 18-8 Stainless Steel

Maximum working pressure

- Up to 600 psig CWP depending on valve series, size and temperature

Temperatures

- Up to 450°F depending on seat and seal material

Polish

- Standard internal polish of 20 Ra ID Series 8, 30 Ra ID Series 9

Find your perfect flow control solution