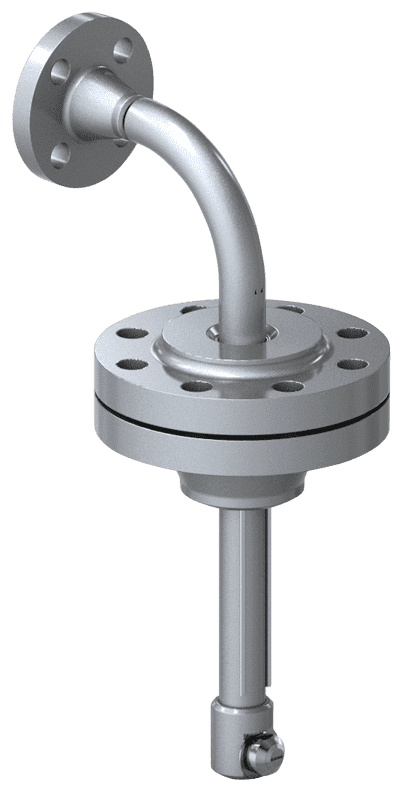

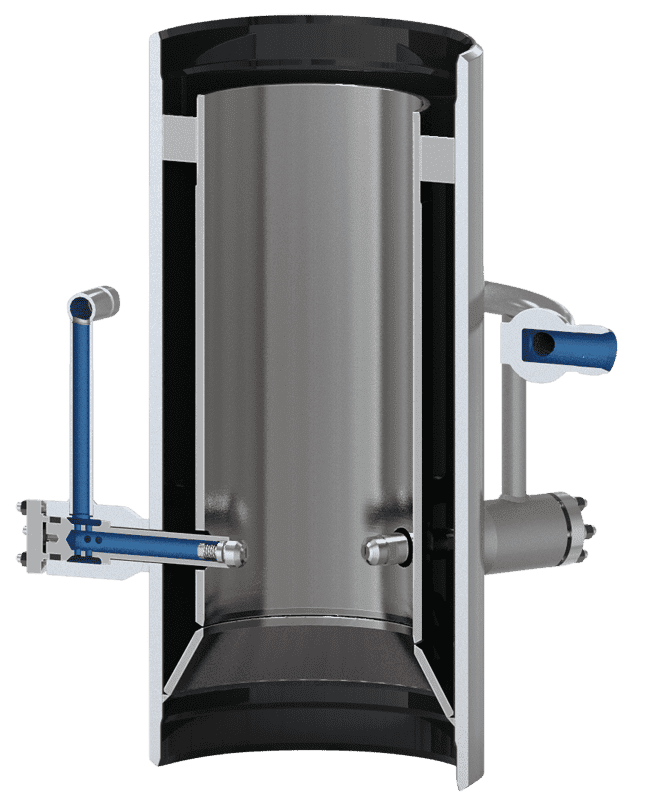

MDAV-S Venturi-style Desuperheater

Venturi-style desuperheater for accurate steam temperature control

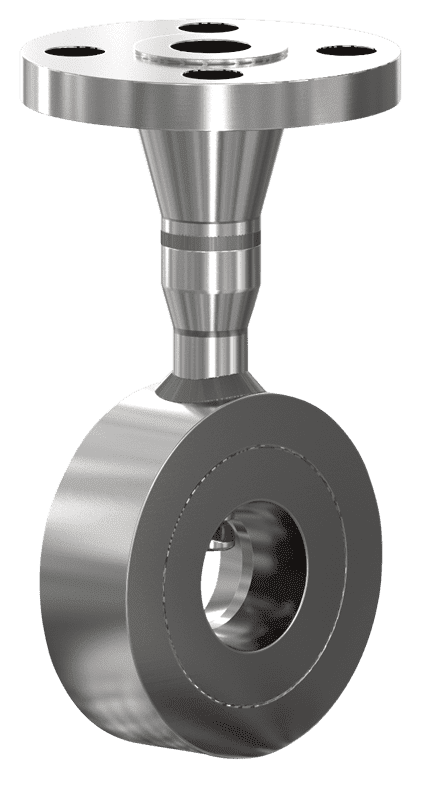

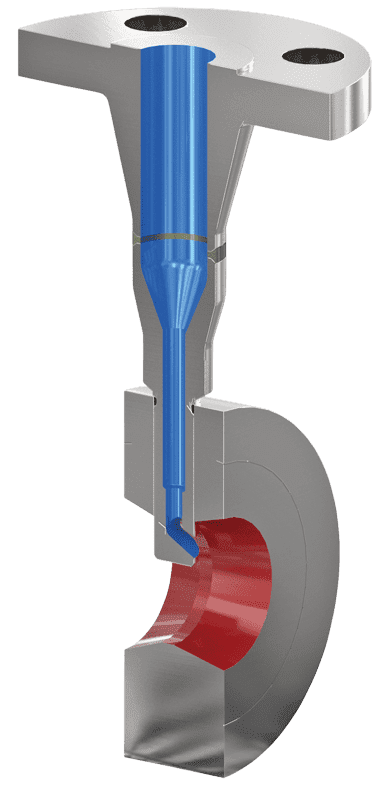

The MDAV-S desuperheater is designed for the attemperation of steam in small diameter pipelines. It features a single spray water nozzle installed into a flange, allowing highly accurate control of the steam temperature down to 8°C / 15°F above the saturation temperature. The spray water is controlled through an external valve and injected into the steam flow through a fixed nozzle. The venturi design guarantees a high steam velocity at the point of injection, which improves water evaporation and minimises the risk of water impingement on the pipe wall.

- Accurate temperature control, down to 8°C / 15°F above the saturation temperature.

- Fast evaporation and atomisation of cooling water thanks to the venturi design.

- Minimal maintenance required – no moving parts.

- Simple, space-saving installation for easy integration into existing systems.

Product Specifications

Nozzle

- Material: EN 10222-2 11CrMo9-10, (S)A-182 F22Cl.3

- Rangeability: Determined by water valve

Design code

- EN 12516-2 / PED

- ASME B16.34

Water connection

- Flange size: 1”

- Material: EN 10222-2 11CrMo9-10, (S)A-182 F22Cl.3

Pressure class

- ANSI 600 or 1500

Steam connection

- Flange size: 2” – 4”

- Materials: EN 10222-2 11CrMo9-10, (S)A-182 F22Cl.3

- Pressure drop: Max 5 bar / 70 psi

Bespoke options

- This product is standardised, with limited options available. If further customisation is needed, the MDAV model is recommended. Contact your local sales agent for more information.

Find your perfect flow control solution