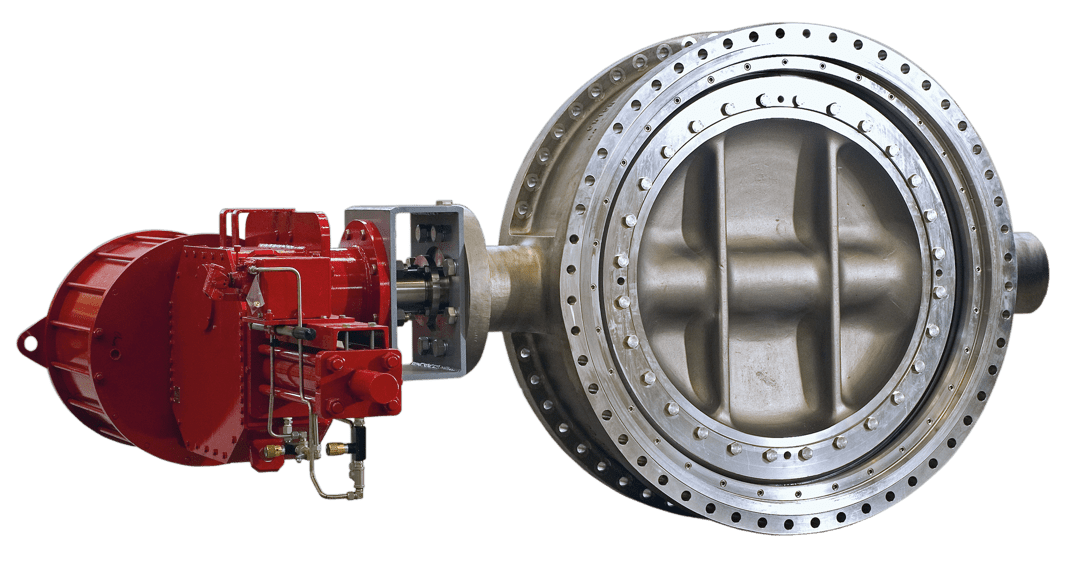

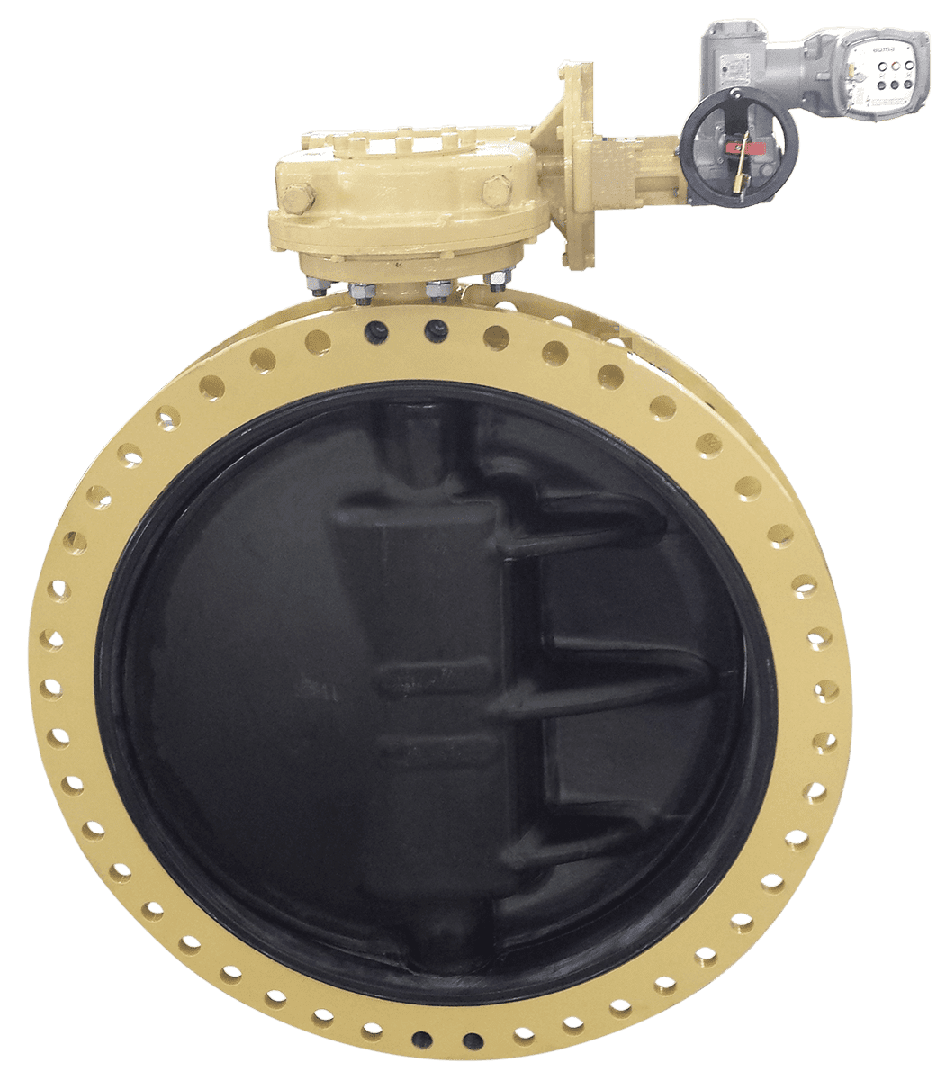

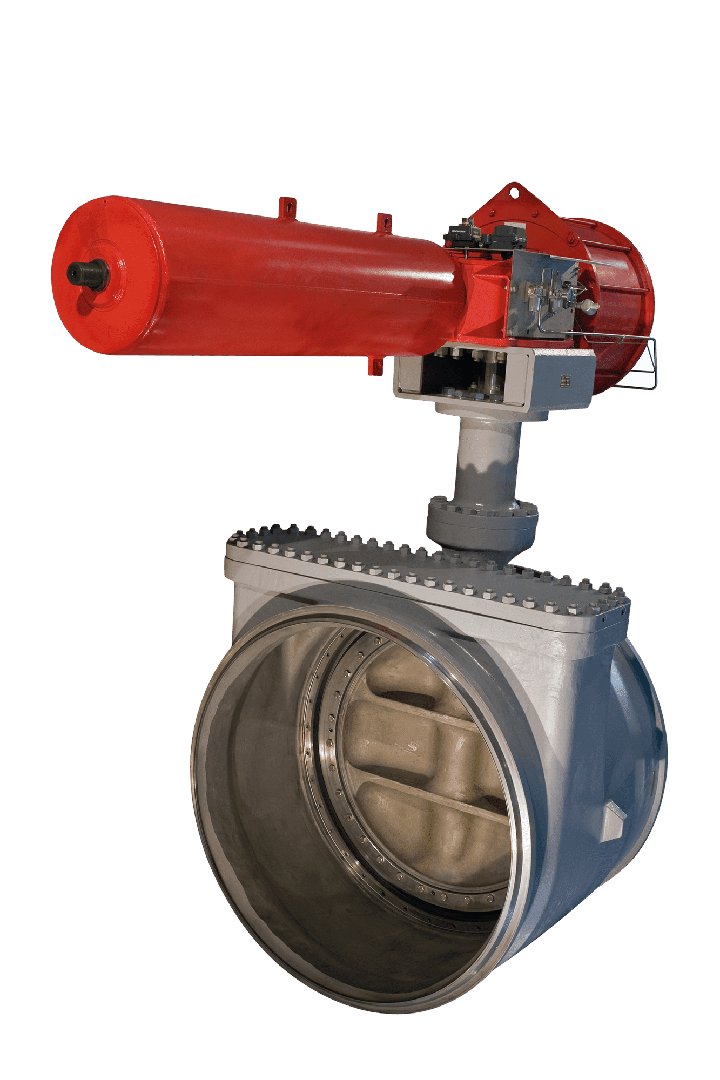

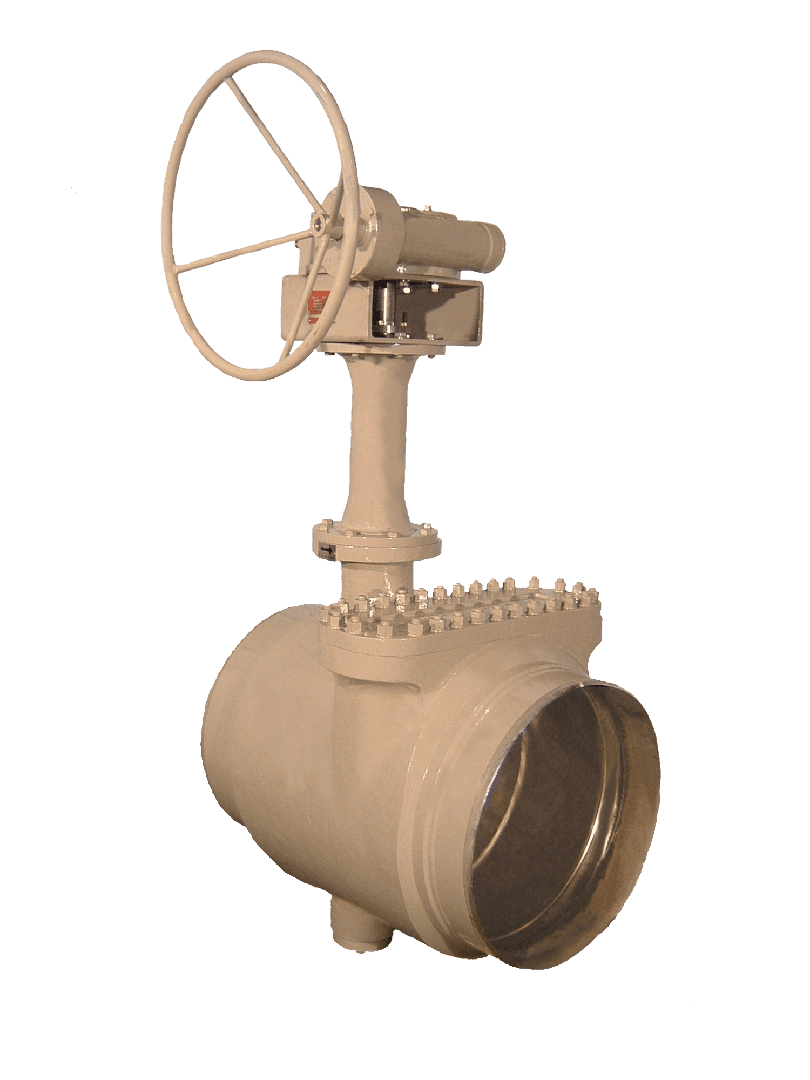

MV Triple Eccentric Metal Seated Cryogenic Valves

IMI Orton’s MV Series valves are renowned globally for their exceptional combination of control, reliability, and compact design. Engineered for critical high-pressure, tight shut-off, high-temperature, or cryogenic applications, these valves are ideal for throttling and isolation duties in demanding environments. The unique triple eccentric design ensures enhanced performance by eliminating wear and leakage, resulting in a longer service life and reduced maintenance needs.

- Triple eccentric design: Prevents wear and leakage, extending service life.

- Resilient metal-to-metal sealing: Ensures robust, tight shut-off performance.

- Quarter-turn, friction-free operation: Minimises operational torque and energy use.

- Fire-safe and fire tested: Compliant with industry safety standards.

- Torque-seated for reliability: Ensures tight shut-off even at high pressures.

- External anti-blowout device: Provides an additional safety feature.

- Bi-directional tight shut-off: Offers sealing in both flow directions.

- Wide range of materials and sizes: Customisable to meet diverse application needs, from -254°C to +426°C.

Product Specifications

Materials

- As suitable list or for all applications

Nominal diameter range

- 2″ – 120″

Temperature limits

- From -254°C (-425°F) up to +426°C (+800°F)

Pressure limits

- Up to +150 bar of shut off differential pressure

Applicable standards

- Design: ASME B16.34 / ASME B16.10 / ASME VIII / API 609 / BS 6755 – API 607 (fire-safe)

- Flange Connection: B16.5 or B16.34

- Butt Weld Connection: B16.25

Rating

- ANSI CI.150 – 300 – 600 and 900

Find your perfect flow control solution