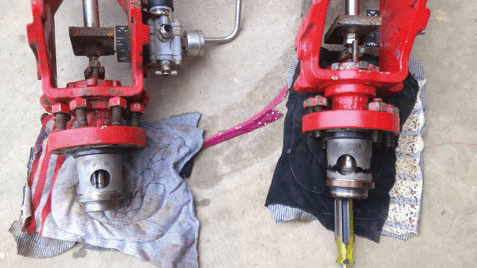

The South American combined cycle plant was facing problems with two of its competitor installed 1-1/2” ANSI 600 class feedwater valves in an intermediate pressure (IP) application. The valves did not perform well in start-up conditions and the valve trim was being adversely affected by cavitation. Multiple upgrade solutions from the incumbent supplier continued to fail.

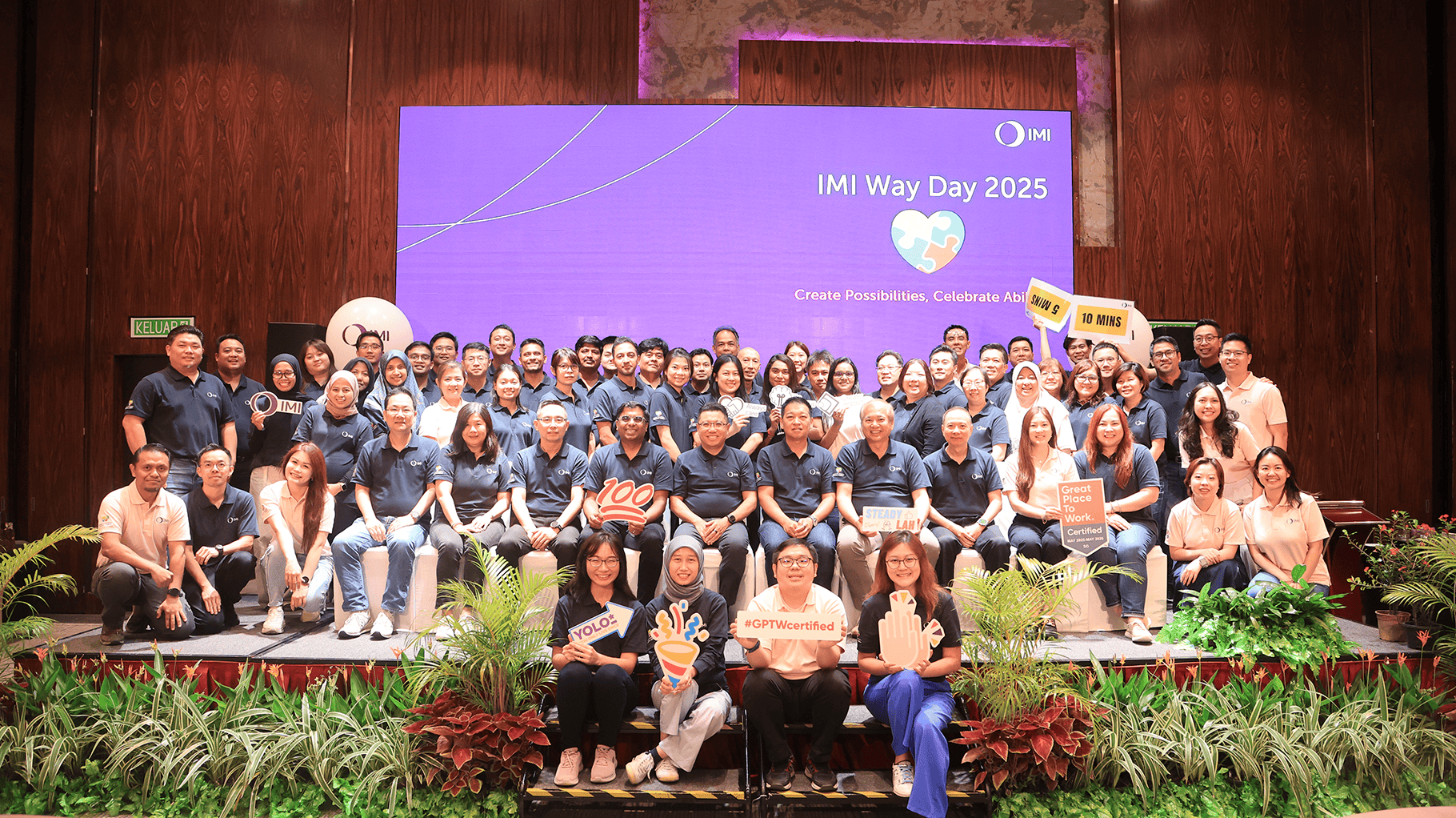

Wear and cavitation of incumbent valves

The customer was looking for a replacement solution that would provide better control of the process and have a longer valve life – reducing equipment and maintenance costs. They approached IMI CCI for a solution because of the reputation of our DRAG® technology and our proven technical expertise in severe service. Key decision makers had also had positive experience of select IMI CCI products in the past.

The IMI CCI solution included the 900D product line to eliminate cavitation problems and provide superior low flow control to improve the process performance.

The customer’s return on investment calculation included a reduction in operation and maintenance cost due to the elimination of damage to valve internals and adjacent equipment and piping.

Our experience and reputation in the industry along with our problem solving capability with DRAG® technology, led to a solution which delighted the customer.