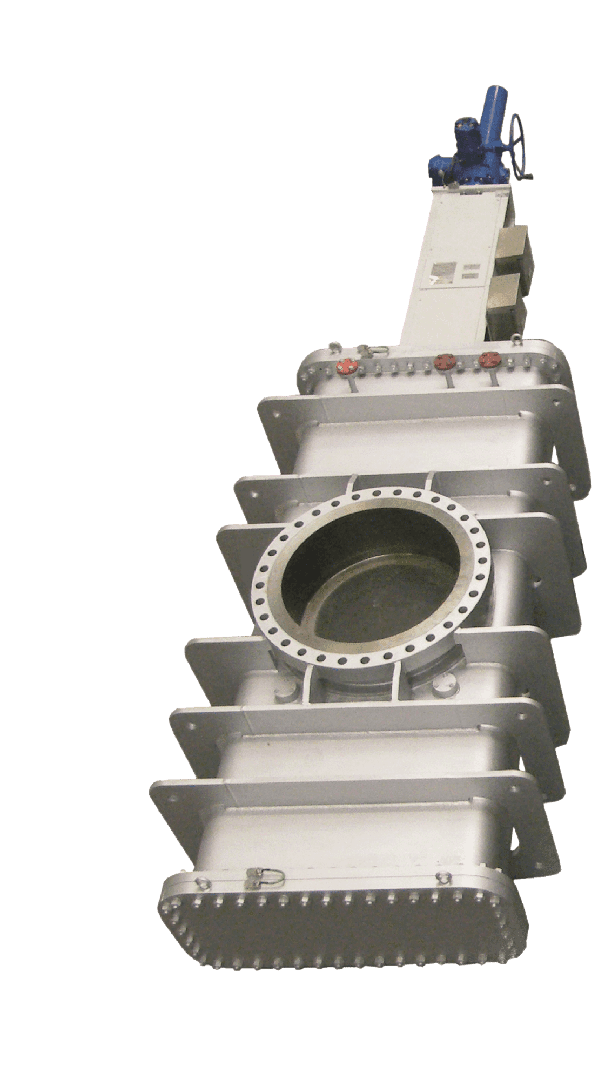

Delayed Coking Bottom Unheading Device

Reliable and safe unheading for delayed coking units

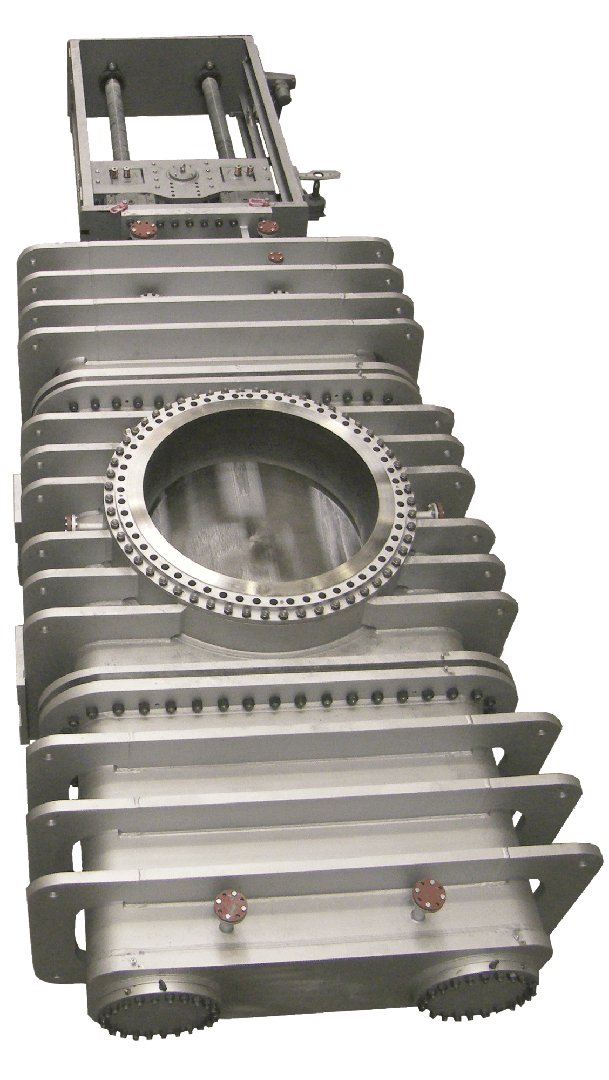

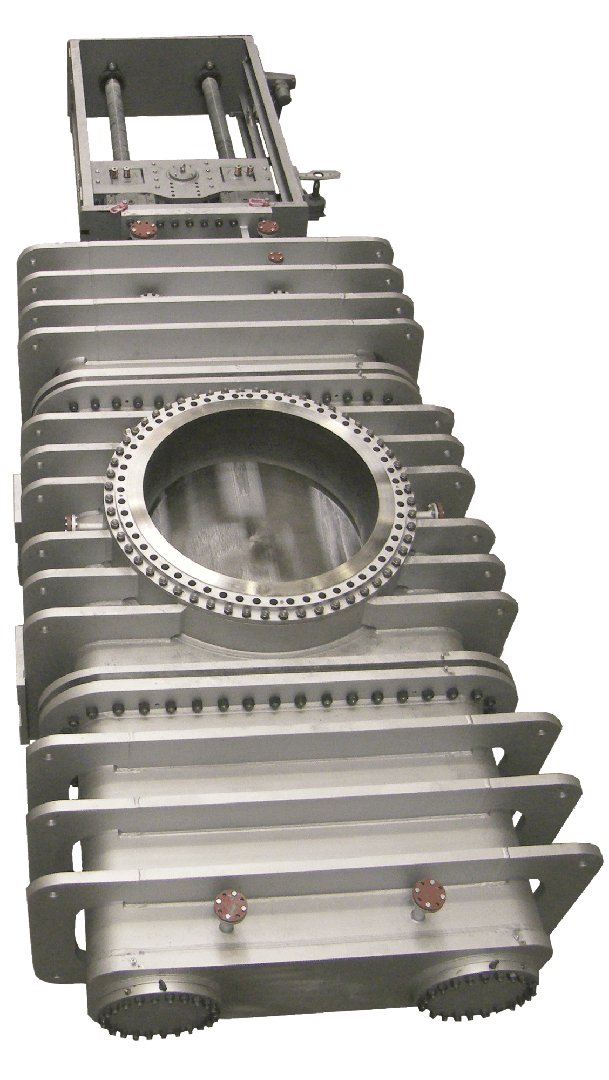

The Delayed Coking Bottom Unheading Device from IMI Z&J is based on the proven Double Disc Gate Valve Technology. This fully automated system ensures reliable and safe operations during delayed coking unheading, reducing risks and optimising efficiency in challenging environments.

- Two independent discs for enhanced sealing.

- Double block and purge for maximum safety.

- Reduced purge steam requirement to lower costs.

- Corrosion and wear resistant design for long-term durability.

- No cooling water requirement for simplified operation.

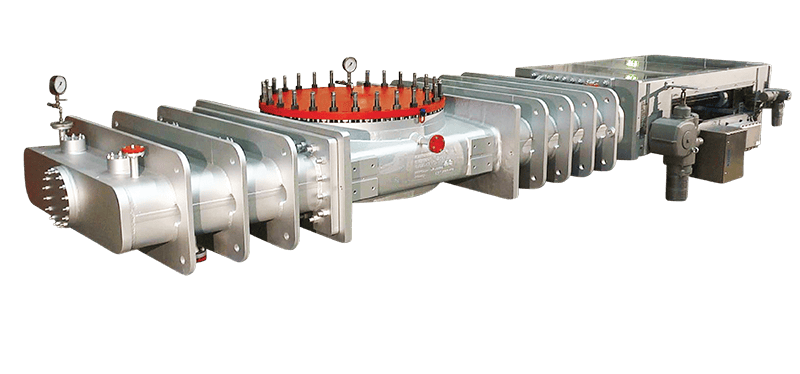

Dimensions

- L 9.7 m x W 2.92 m x H 1.3 m (L 382″ x W 115″ x H 51.5″)

Weight

- 61,500 kg (135,600 lbs)

Operating media

- Steam for purge

Ambient temperature range

- -40°C to +60°C (-40°F to 140°F)

Leakage rate

- API 598 compliant

Find your perfect flow control solution